- 20 -

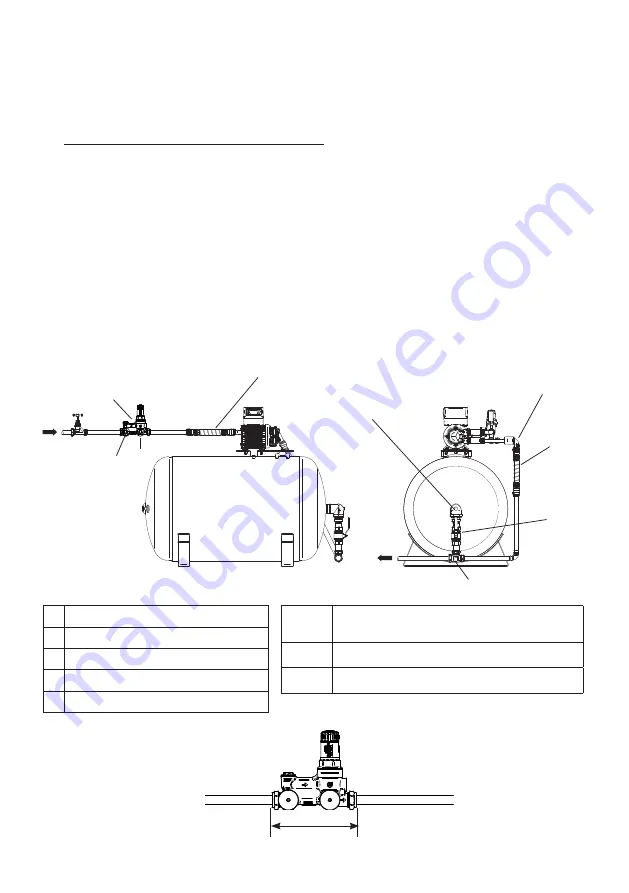

Horizontal Step 2:

The vessel assembly should then be positioned and checked to ensure there is

sufficient space to install the upstream line-in kit between the stopcock and

pressure vessel inlet. Refer to the chart below as a guide.

Monobloc 22/28mm Upstream line-in kit

The Monobloc upstream line-in kit includes:

1 - Monobloc unit

2 - Pressure gauge (upstream)

3 - Pressure gauge (downstream)

4 - Vessel Connector (see step 1)

5 - Isolation Valve (see step 1)

NOTE: the Monobloc can be installed either horizontally or vertically but not upside

down. There are pressure gauge ports on both sides of the Monobloc to allow the

pressure gauges to be visable in any orientation. Follow the directional flow arrows

on the Monobloc to ensure correct installation.

NOTE: It is good practice to install a drain port between the isolation valve and the

vessel.

1 Monobloc unit

2 Pressure gauge (upstream)

3 Pressure gauge (downstream)

4 Mainsboost vessel connector

5 Lever isolating valve

Fig. 24a

Pipe

Size

Minimum pipe length required to install

the Monobloc upstream in line kit (mm) (A)

22 mm 203 mm

28 mm 203 mm

A

Inlet

Outlet

1

2

Flexible

hose

4

5

Flexible

hose

3

Fig. 23a

Push fit elbow

(not supplied)

T-piece (not supplied)