Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

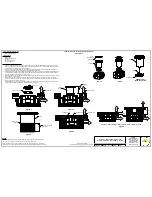

Adapter

Adapter

Cover

Cover

Gasket

Gasket

OS-100

(standard)

Upper clamp

Lower clamp

Lower clamp

Upper clamp

Cut location "C"

LR24

(long riser)

(optional component)

Gasket

Upper Clamp

Lower Clamp

Cut location "B"

SR24

(short riser)

(optional component)

Gasket

Lower Clamp

Upper Clamp

OS-35, OS-50,

OS-75 & OS-100

(standard)

Adapter

Cover

Gasket

Upper clamp

Lower clamp

VENT

FLOW

Finished floor

Figure 1

Riser Height

Adapter

Unit

Figure 2

Adapter

Riser

Riser

Distance from step 5

4"

Cut

Mark

Figure 3

Adapter

Riser

exceed 4"*

Must be at least

2-1/2" and cannot

Gasket

Unit

Riser/Adapter

Upper Clamp

Lower Clamp

Figure 4

*3" for a OS-35 with 4" connections

5. Adjust

adapter

upwards to reach 20" to 22"

6. Adjust

adapter

upwards to reach 35" to 37"

Cut location "A"

Adapter

Cover

Adapter & Cover

(standard component)

Tools included (with base grease interceptor unit(s))

7/16" Nut driver tool/bit

•

Silver permanent marker

•

Tools Needed:

Tape measure

•

Regular or cordless drill with 1/2" chuck

•

Tools needed if Riser(s) require cutting:

Jigsaw or

•

Cordless circular saw or

•

Reciprocating saw

•

Riser Assembly Instructions/Steps:

If unit is to be installed on grade (on-the-floor), there is no need for any adjustments.

1.

Unit is ready to be put into service.

If unit is to be buried: Once unit is set so that the pipe connections line up with

2.

jobsite piping, measure total riser height needed from top of cover to finished

grade. Make sure you include any future tile work, etc. that may be installed

in your finished grade measurements. See figure 1.

Select according riser(s) needed based off Table 1.

3.

If riser(s) is needed, remove cover(s) from adapter and remove adapter from main

4.

unit by loosening upper clamp with included nut driver bit (lower band is factory

set do not adjust or remove). On the floor near the unit, insert adaptor into first riser

until it stops. If needed, insert bottom of first riser into top of second riser until it stops.

You may need to tighten upper clamps during this step to keep risers from shifting.

Adapter and riser(s) should sit level with each other. Removal of cover during this process

will ease assembly.

From the top of the adapter, measure your needed total riser height downward to the

5.

sidewall of the riser. Then, add

5”

(for OS-35 or OS-50) or

6”

( for OS-75, or OS-100).

For example, if you have a OS-100 and need a 15-1/2” extension, you would measure

down from the top of the adapter 21-1/2” (15-1/2” + 6” = 21-1/2”). See Figure 2.

Refer to Table 2, Table 3 or Table 3a to determine if, and where, any cuts need to be made.

6.

If a cut needs to be made, make a circular line around the sidewall of the riser with the

included silver marker at your riser height

+dimension from step 5

. Using a jigsaw, circular

saw or reciprocating saw, cut along your line. Discard/recycle the cutoff scrap.

Whether the riser needs to be cut or not, make another mark with the silver marker on the

7.

sidewall of the riser a distance of

4 INCHES

(3 INCHES for a OS-35 w/ 4” connections) above

the edge just cut. If you did not make a cut (meaning your riser height

+ dimension from

step 5

line was beyond the bottom edge of your riser), still mark the sidewall of the riser

4 INCHES above where your riser height

+ dimension from step 5

line would have been.

DO NOT cut this new line. Once the riser is installed into the main unit, this new line will end

up at the top of the gasket and will aid in re-assembly. See Figure 3.

IMPORTANT: Before the next step:

8.

Make sure both diffusers are installed inside the main unit at the appropriate locations

and check if there needs to be any flow control adjustment on the inlet diffuser. Refer

to sheet 2 of the installation instructions for flow control adjustment.

Refer to sheet 1 of the installation instructions for leak/water testing procedures.

9.

Take riser(s) and adapters apart to reduce the weight during installation. Wipe all sidewalls and

10.

inside of gasket with a damp cloth to remove jobsite dust/debris. Install components into the main

unit starting from the lowest (cut) riser and working your way toward the finished floor level. Upper

clamps at each gasket need to be loosened or removed to aid in assembly. Once riser(s)/adapter

is inserted into gasket, upper clamp can be tightened.

Verify that the bottom of the lowest riser is protruding at least 2-1/2” but no more than 4” into

11.

the main unit from the top of the gasket. Your mark from step 7 should be at the top edge

of the gasket on the main unit. If measurements were made correctly, this should happen

automatically. See figure 4.

If tilting of the adapter is required to be flush with finished grade, it must be done AFTER all

12.

clamps have been tightened with riser(s)/adaptor in a vertical and level position. Tilting is

achieved by using the flexibility of the gasket. If tilting is done before clamps are tightened, a

perfect gasket seal may be compromised. Schier recommends tilting only the adapter versus the

entire riser assembly to make sure your riser height is maintained.

Tighten all clamps to a minimum of 5 and a maximum of 8 ft lbs. of torque. Use the same torque

13.

as you would tighten a rubber no-hub coupling.

The adapter must be adjusted

upward

to achieve certain extension heights. See Table 2,

14.

Table 3 or Table 3a.

If jobsite riser height conditions change after the above steps have been completed, there

15.

may still be room for vertical adjustment in both directions. As long as minimum and maximum

overlaps are maintained (see Figure 4), the adapter/riser(s) can be adjusted/cut as many times

as necessary. Please follow these steps from the beginning to ensure the proper overlaps are

maintained.

1. Adjust

adapter

upwards to reach 22" to 24"

2. Adjust

adapter

upwards to reach 37" to 39"

3. Adjust

adapter

upwards to reach 56" to 58"

4. Adjust

adapter

upwards to reach 70" to 72"

5. For OS-75 , Adaptor will need to be cut short at

location "A" to reach 0"- 3-1/2" due to oprn top

Deffuser.

7. Adjust

adapter

upwards to reach 19" to 21"

8. Adjust

adapter

upwards to reach 34" to 36"

TeleGlide Riser (24 Series) Installation Guidelines

(OS-35, OS-50, OS-75, OS-100)

Call Striem with questions or suggestions @ 1-913-222-1500 Customer Service Hours: 8AM-5PM CST

OS & OCT SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

8/16/18

MJ

REV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem oil separators are rated and manufactured with an internal flow control system already in

place. They do not require an external flow control system or air intake vent.

Striem oil separators are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SHEET NUMBER:

6 of 7