18

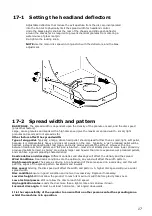

18-1 Setting the feed rate

The feed rate is adjusted by the feed motor speed and by fitting different feed roller combinations.

Each combination giving different feed rates of material per revolution. Refer to the Calibration Procedure and

with the appropriate feed rollers fitted, follow the instructions. You may have to change the feed rollers to

obtain the application rate within a sensible forward speed range which is calculated during the calibration

procedure.

When re-fitting the end plates to the feed block after changing the configuration, the end plate should be able

to fit flush with the feed block by hand, without having to pull it home with the socket head screws.

The assembled rollers and spacers should not be under compression.

NOTE.

You should be able to rotate the feed shaft with your fingers – if it feels excessively tight, check the

feed roller and spacer composition or call Stocks AG for advice.

WARNING

Always observe all application standards and guidelines provided by the

product manufacturer as some products may be toxic !

If unsure contact your supplier for more information.

NOTE

always ensure a stainless

disc is fitted to each side of the set

of 1,2,3,4 or 5 feed rollers used in

each half of the feed block.

They are important and needed to

reduce friction between the feed

rollers and the plastic spacers.

Photo of a feed block assembly with 6

feed rollers and 6 blacking spacers fitted

18-2 Feed roller configuration

For higher outputs or applying large seeds or granules the

machine is also supplied with 2 larger 8 section feed rollers

and spacers to allow 1 or 2 to be fitted as required.

The feed rollers are easily changed by removing the feed

block as follows.

NOTE Empty the hopper completely before removing

the feed block.

Photo of a feed block assembly with 2

larger 8 section feed rollers fitted

1.

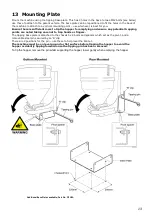

Undo and remove the 2 black

plastic knobs holding the feed block

in place

2.

Slide the complete mechanism out

3.

Undo and remove the 4 socket

head screws on the end of the

housing opposite the retaining plate

and remove the end plate

4.

Slide the rollers and spacers off

the shaft, and replace with the

alternative rollers and spacers in the

required combination

5.

Refit the end plates and re-fit the

feed block and black plastic knobs.

The machine is fitted 10 white 5mm polyurethane 18 tooth feed

rollers as standard these have a stainless steel drive disc embed-

ded. Depending on the combination of required seeding rate,

implement width and forward speed 2 to 10 feed rollers can be

fitted with maximum rates achieved by fitting all 10 feed rollers.

The black 5mm wide spacers supplied are the same width as the

white feed rollers and used to replace feed rollers as required