EN - 10

6.1.3 Tyre pressure

Having the right tyre pressure is the main

condition for ensuring that the cutting-means

assembly is horizontal and mows evenly.

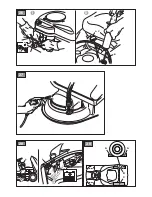

1.

Unscrew the valve caps

2.

Connect a compressed air line with

a gauge to the valves (fig. 14)

3.

Adjust the pressure according to the values

indicated in the "Technical Data" chart.

6.1.4 Preparing the machine

before starting work

NOTE

This machine can be used to

mow lawns in a number of different ways;

before starting work, prepare the machine

based on how the lawn is to be mowed.

a. Prepare the machine for side cutting and

discharge of the grass onto the floor

– Always make sure that the spring inside

the deflector (Fig. 13.A) and the safety

lever (Fig. 13.B) operate correctly,

holding it firmly in the lowered position.

b. Preparation for mowing and

mulching of grass

– If you decide to mow the grass, mulching

it and leaving it on the grass, a "mulching"

kit is available upon request (chap.

15.1). This has to be attached to the rear

plate as indicated in the instructions.

IMPORTANT

The “Mulching” function can

only be carried out by using specific cutting

means (not included in the kit), bearing the

code indicated in the “Technical Data”.

6.1.5 Positioning the anti-scalp wheels

The anti-chipping wheels are used to reduce

the risk of tearing up sections of lawn, which

can occur when the edge of the cutting-means

assembly drags over irregular ground.

Position the wheels as indicated (par. 7.4).

6.2 SAFETY CHECKS

Run the following safety checks and

check that the results correspond to

those outlined on the tables.

Always carry out the safety

checks before use.

6.2.1 General safety check

Object

Result

Battery

No damage to the casing,

cover or terminals

Side discharge guard

Good condition. No

damage. Properly

installed.

Fuel lines and

connections.

No leaks.

Electrical cables.

All insulation intact.

No mechanical damage.

Oil lines

No leaks.

No damage.

Drive the machine

forwards and backwards,

shift to neutral /release

the drive pedal (par. 5.5)

The machine slows

down and stops

Press the brake

pedal (par. 5.4)

The machine stops

Test driving

No abnormal vibrations.

No abnormal sound

Safety devices

Proceed as indicated

in par. 6.2.2

6.2.2 Control of safety devices

The safety devices work in two ways:

A.

they prevent the engine from starting if all

the safety requirements have not been met;

B.

by stopping the engine if even just one

of the safety requirements is lacking.

Action

Result

1. gear in “neutral”;

2. cutting means

disengaged;

3. operator seated.

The engine starts

the operator leaves his seat

The engine stops

the parking brake is engaged

without disengaging

the cutting means

The engine stops

the speed change is

activated or the drive

pedal with the parking

brake engaged

The engine stops

the reverse gear is engaged

with the cutting means

engaged, without pressing

the consent button (par. 5.8)

The engine stops

If any of the results fails to match the

indications provided in the tables, do not

use the machine! Contact a service centre to

have it checked and repaired if necessary.

Summary of Contents for SDNSL 108 Hydro

Page 2: ......

Page 3: ...ITALIANO Istruzioni Originali IT ENGLISH Translation of the original instruction EN ...

Page 5: ...5 3 A B C D E A F G H A A B C 4 B C C A 6 A B C D E ...

Page 6: ...7 I II A C C B OK NO A B C D D E F F G G 8 9 ...

Page 7: ...10 A B B C C 11 B 2 A C B 2 A D C B D 1 E D E 1 A B B 1 B B ...

Page 8: ...12 J A B C D E E 1 F G H I L E F II I 13 14 A A ...

Page 9: ...15 A B 16 B A 17 A H H 30 mm H 10 mm H 20 mm H 0 mm A C B D 18 max 10 17 19 A 20 1 3 21 A B ...

Page 10: ...22 A 23 24 25 B C A ...

Page 11: ...27 A B C A B C A 26 I II A A 28 29 A A B C ...

Page 12: ...A 110 mm 30 31 32 33 B A C C 34 A D B C 35 A B A A B C ...

Page 13: ...36 A A 37 38 B C D A2 ...

Page 38: ...STIGA S p A Via del Lavoro 6 31033 Castelfranco Veneto TV ITALY Type s n Art N stiga com ...