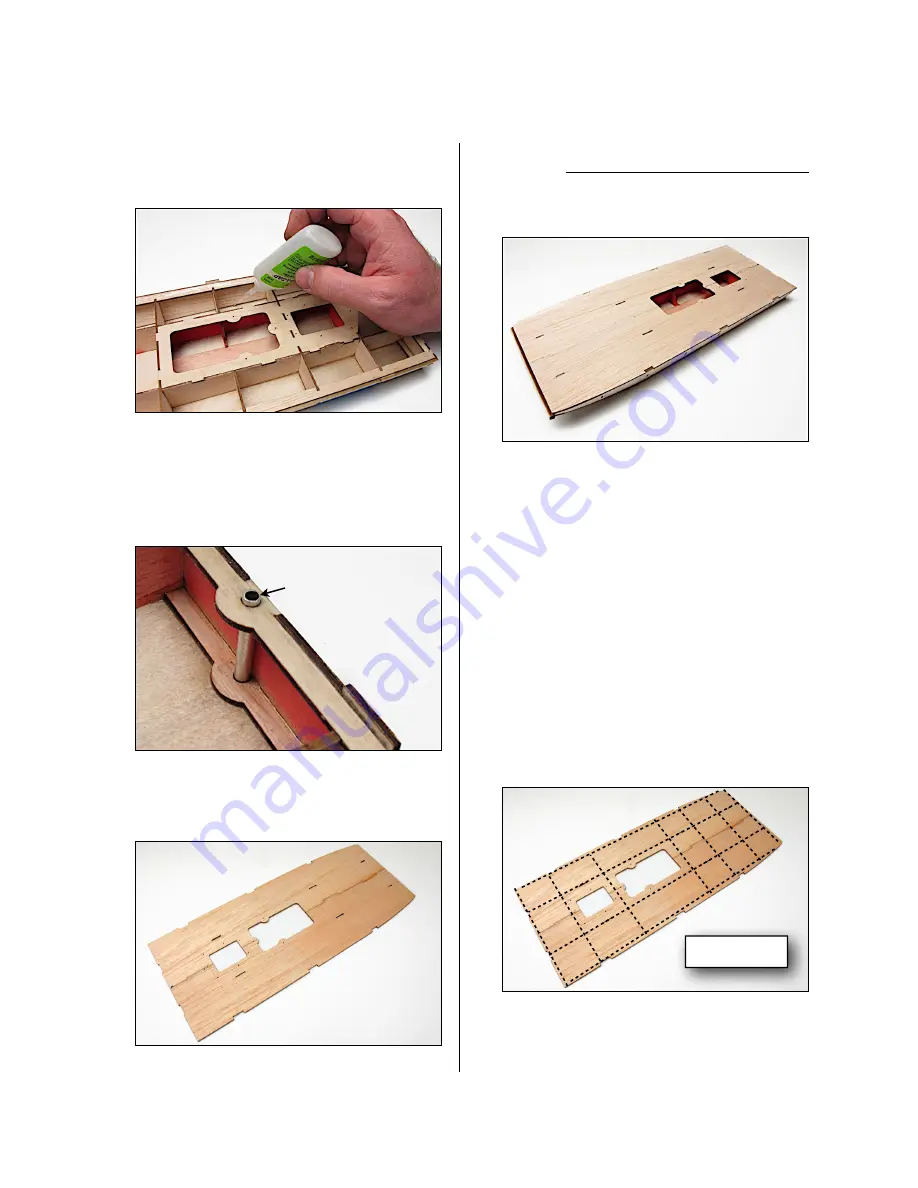

Hull Construction Continued

☐

Working back from the bow of the boat bond

all intersections of formers, ribs, and hull

bottom aft of former F2.

☐

Cut the provided 1” length of aluminum tubing

to 15/16” and install at the transom within the

circular cutouts of F10 and F11 as illustrated

below. Note that tube will protrude ~ 1/16 in.

above the plywood F10 former. Bond with

medium CA to retain part within assembly.

☐

Join parts D1a and D1b along the dove-tail

joints to create the “D1” upper decking. Bond

with thin or medium CA glue along the seam.

☐

Test fit the D1, upper decking assembly, to

the hull

with the dashed etch lines down.

Make any adjustments to the tabs and

notches to ensure you can quickly drop this

part into position atop the hull assembly.

☐

Remove the D1 decking and lay on your

worktable etch side up.

You’ll need to work quickly on this step. Thick

CA glue or 5 min. epoxy will ensure proper

working time. Apply glue along the perimeter

of part D1, around the radio access hatch

holes, and along each of the dashed lines

etched on D1.

Key the pre-fit, and now glue covered, D1

balsa top deck (glue/etch side down) to tabs

along side of boat and at ribs and set into

position. Pinch around top decking and F9

sub deck to make certain you have achieved

a proper bond. Especially in the area of the

electronics access hatch, go over all joints

and edges and make certain the deck is

properly seated.

Build Instructions

© 2013 Stevens AeroModel all rights reserved.

Page 11 of 25

Bottom View

Transom

1/8” Diameter x 15/16”

Length Aluminum Tubing