I

ntegrated Stepper Motor Driver ISD02/04/08

5

the output current.

For ISD02, a mapped voltage “Va” of 0 - 2V proportionally represents 0 - 2A.

For ISD04, a mapped voltage “Va” of 1. 5 - 4V proportionally represents 1. 5 - 4A.

For ISD08, a mapped voltage “Va” of 1. 5 - 4V proportionally represents 3 - 8A.

Note

:

The driver needs to be powered before mapped voltage “Va” can be measured. (Motor is not required to

be connected at this time. )

DIP1 (on the bottom side DIP switch 2) needs to be turned off to shut down the ACR Function.

After adjustment, user can choose to turn on the DIP1 to enable the automatic current reduction.

Current Adjustment

Trimmer

Before measuring Va:

1) Apply Power

2) Turn off DIP

Voltmeter

Mapped Voltage

Va

Bottom Side

12 ~ 40VDC

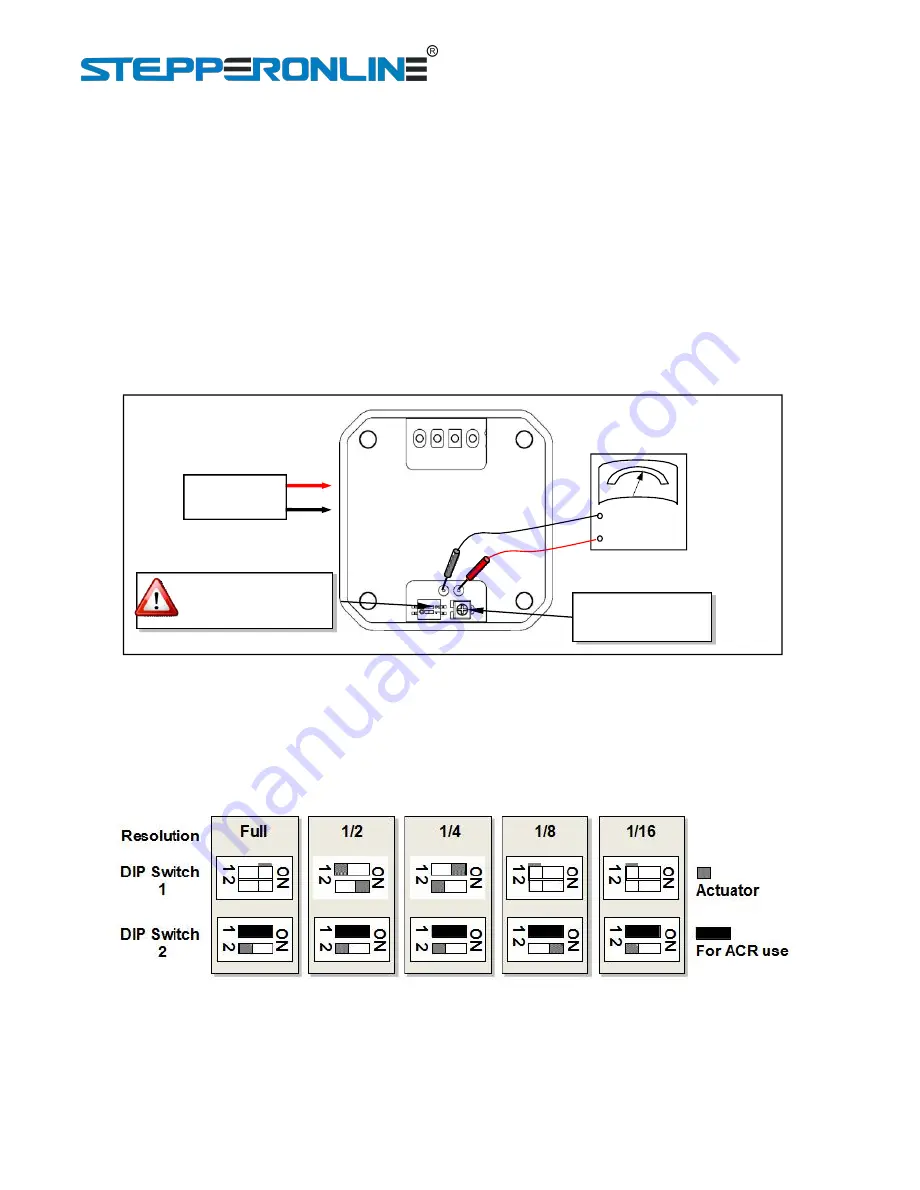

Figure 5: Adjusting the Output Current

5.2 Microstep Resolution

The microstep resolution is set by both DIP switch 1 and DIP switch 2 located at top and bottom side of

the driver as shown in following figure. ISD02/04/08 driver can provide microstep control at 200, 400, 800,

1600, 3200 step resolutions.

Figure 6: Microstep settings

5.3 Power Supply Selection

ISD02/04/08 drivers accept a wide range input voltage from 12 to 40VDC. (ISD02 takes 10 - 28 VDC) In

general, higher supply voltage improves motor performance under high speed situation, but also increases

the power loss and temperature raise.