- 53 -

CLRS Series RS485 Closed Loop Stepper Drive User Manual

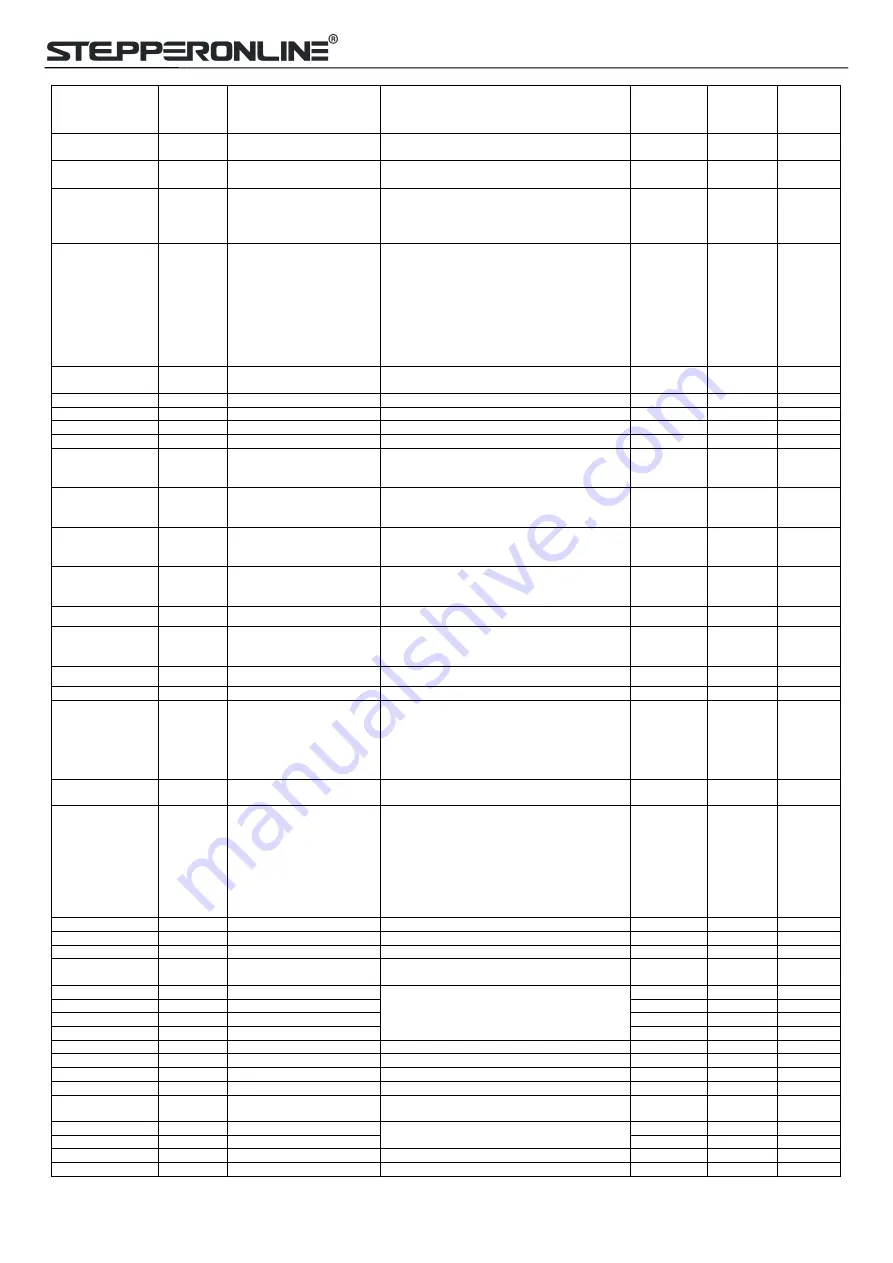

0x23: in-position completed;

0x24: brake output;

0x25: alarm output;

0x015B

Pr4.13

SO3(output 3)

0-65535

0

--

0x0167

Pr4.19

Delay of brake released

Keep default normally

0-1500

250

ms

0x0169

Pr4.20

Delay of brake locked

Keep default normally

0-1500

250

ms

0x016B

Pr4.21

Threshold value of brake

locking velocity

Keep default normally

0-500

10

--

0x016D

Pr4.22

Alarm detection selection

Bit setting:

=1: Yes; =0: No

bit0: over-current (Cannot be changed)

bit1: over-voltage

bit2: position following error

bit3: ADC sampling failure

bit4: Locked shaft alarm

bit5: EEPROM alarm

bit6: Auto-tuning alarm

0-65535

0

--

0x0171

Pr4.24

Distance to send

"In

Position" output signal

The distance (in number of pulses) to send out

the In-Position signal

0-1500

200

CPR

0x0177

Pr4.27

Bus voltage

0-65535

0

0.1V

0x0179

Pr4.28

Digital input statue

Bit0-Bit6: SI1-SI7

0-65535

0

--

0x017B

Pr4.29

Digital output statue

Bit0-Bit2: SO1-SO3

0-65535

0

--

0x0187

Pr4.35

DIP switches statue

0-65535

0

--

0x0191

Pr5.00

Peak current

Approximately equal to motor phase current

value multiplied by 1.2 -1.4

503: 3-30

507: 5-70

1008: 5-80

503: 25

507: 60

1008: 80

0.1A

0x0193

Pr5.01

Percentage

of

holding

current

in

closed-loop

mode

It is recommended to keep default, If the

torque is not enough, it can be increased

appropriately

0-100

50

%

0x0195

Pr5.02

Percentage

of

holding

current in open-loop mode

It is recommended to keep default, If the

torque is not enough, it can be increased

appropriately

0-100

50

%

0x0197

Pr5.03

Percentage of shaft locked

current(power on)

Keep default normally

0-100

100

--

0x0199

Pr5.04

Shaft locked duration

Keep default normally

0-1500

200

1ms

0x019F

Pr5.07

Rising time of shaft locked

current (power on)

Keep default normally

1-60

1

100ms

0x01A5

Pr5.10

The max stop time

Keep default normally

100-1000

1000

ms

0x01AB

Pr5.13

Auto-tuning at power on

0: disable, 1: enable

0-1

1

--

0x01BD

Pr5.22

RS485 baud rate

0: 2400 1: 4800 2: 9600 (default)

3: 19200 4: 38400(factory) 5: 57600

6: 115200

When SW6 and SW7 are all OFF, it can be set

by PC software.

0-6

4

--

0x01BF

Pr5.23

RS485 ID

When SW1 - SW5 are all ON, it can be set by

PC software

0-127

1

--

0x01C1

Pr5.24

RS485 data type selection

0: 8-bit data, even check, 2 stop bits;

1: 8-bit data, odd check, 2 stop bits

2: 8-bit data, even check, 1 stop bit;

3: 8-bit data, odd check, 1 stop bit:

4: 8-bit data, no check,1 stop bit:

5: 8-bit data, no check,2 stop bits;

0-11

4

--

0x01C3

Pr5.25

RS485 control word

0-32767

0

--

0x01C4

Pr5.26

Communication bit delay

0-100

35

bit

0x01D1

Pr5.32

Switching time to standby

10-65535

200

ms

0x01D3

Pr5.33

Standby

current

percentage

0-100

50

0x01E1

Pr6.00

JOG velocity

This JOG is triggered by RS485.

For JOG triggered by IO, please use

Pr8.40/8.41

0-5000

60

r/min

0x01E3

Pr6.01

Interval

0-10000

100

ms

0x01E5

Pr6.02

Running times

0-30000

1

--

0x01E7

Pr6.03

Acc. / Dec. time

0-10000

200

--

0x01FF

Pr6.15

Version information

Read only

0-65535

0

--

0x0201

Pr6.16

Firmware information

Read only

0-65535

0

--

0x0231

Pr7.00

Motor model

Invalid

0-100

0

--

0x0235

Pr7.02

Back EMF coefficient

Invalid

0-32767

100

1ms

0x0237

Pr7.03

Current loop proportional

KP

Invalid

0-3000

1500

--

0x0239

Pr7.04

Current loop KI

It is recommended to keep the factory value,

when disable auto-tuning, can be modified

0-1500

300

--

0x023B

Pr7.05

Current loop KP

0-1024

100

--

0x023D

Pr7.06

Current loop Kc

Invalid

0-32767

300

--

0x0243

Pr7.09

Over-voltage threshold

Invalid

0-1000

90

V