Specialised Tools and Equipment Ltd

12

6.

ROUTINE MAINTENANCE

Ensure that the battery is removed from the drill before any maintenance or adjustments

made to the machine. All maintenance must be carried out by trained personnel.

The following outlines the

minimum

requirements for the maintenance for the Rail Drill.

6.1.

Slide Adjustment

•

After repeated use the cradle may become loose

and will need to be tightened.

•

Insert a 2mm Allen Key into the head of the slide

adjustment screw. Rotate clockwise to tighten the

slide.

•

Gently tighten the screws in series until the cradle

moves freely in the slide but does not allow the

motor to wobble.

•

When adjustment is complete re-tighten locking

nuts clockwise

6.2.

Changing the Battery

Press in the two battery retaining clips and withdraw the

battery from its seat.

Fitting is the reversal of removal.

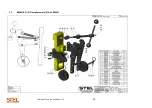

Summary of Contents for 100001

Page 15: ...Specialised Tools and Equipment Ltd 15 7 2 BRDM18 FUEL Clamp Assembly Pt No 100024 ...

Page 17: ...Specialised Tools and Equipment Ltd 17 ...

Page 19: ...Specialised Tools and Equipment Ltd 19 ...

Page 20: ...Specialised Tools and Equipment Ltd 20 ...

Page 21: ...Specialised Tools and Equipment Ltd 21 ...

Page 24: ...Specialised Tools and Equipment Ltd 24 NOTES ...