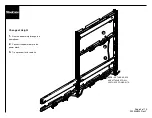

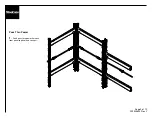

Communication/Data Port Template

Receptacle

Template

Match Receptacle Back Color to Block Color for proper keying.

Impression

NOTE:

Be sure electrical

products are in final position

before making Impressions

1.

Install receptacles into

power block.

2.

Place Communication and

Receptacle Templates.

Steelcase Part No. T500940SR.

(Customer Service)

3.

Attach skin to frame. press

against template to make impression.

Remove skin and template.

OR

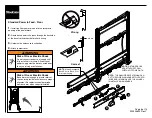

RECEPTACLE

FLEX RECEPTACLE

Page 3 of 10

939504633 Rev Y

OR

USB RECEPTACLE

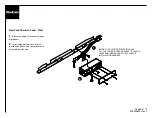

NOTE: This equipment has been tested and

found to comply with the limits for a Class

A digital device, pursuant to part 15 of the

FCC rules. These limits are designed to

provide reasonable protection against

harmful interface when the equipment is

operated in a commercial environment.

This equipment generates, uses and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a residential

area is likely to cause harmful interference

in which case the user will be required to

correct the interference at his own expense.

Risk of Fire or Electric Shock

• Receptacle Templates should always be

used when marking receptacle locations

on the back of panel skins.

• If the templates are not used, then cut

opening 1-1/2" x 3-5/8", allowing clearance

for the mounting screws.

WARNING