III. General Maintenance

Warning! Any mechanism or load held in

position by the brake should be secured to

prevent possible injury to personnel or damage

to equipment before any disassembly of the

brake is attempted or the manual release lever

is operated on the brake. Observe all

cautions

listed at the beginning of this manual.

Note 1: Replacement part kits for many items

are available and contain retrofit instructions.

Note 2: Do not lubricate any part of the brake

as this may cause a malfunction and/or loss of

torque.

A. Coil replacement

All standard NEMA AC voltage coils are

available in kits. Select coil kit from appropriate

replacement parts list for the particular brake

series being serviced.

All standard NEMA DC voltage coils are

available in assemblies and may also be

obtained from appropriate parts list.

B. Friction disc replacement

Note: Replace friction discs in single disc

brakes when wear surface area is one half the

original disc thickness (1/4”). In multiple disc

brakes, replace all friction discs when throat of

lever arm (17) is within 1/16” of touching teeth

of pinion (32).

1. Replacement friction discs for use with either

square or splined brake hubs are available

in kits. Select applicable kit from appropriate

parts list for the brake being serviced.

2. If brake uses metal carrier rings with bonded

friction linings (P/N 5-18-7001-00) for use

with splined hub obtain required quantity.

Then proceed as follows:

a) Observe cautions and warnings

preceding

Installation Procedure

,

Section I. Follow Steps L and K then

disconnect solenoid lead wires.

b) Continue with Steps C through E and

Steps G through L. Be sure to reconnect

coil leads before replacing housing (7).

C. Other standard replacement parts

The standard 87,700 Series brakes use

replacement part kits or components

depending on the items involved. Consult Parts

List P/N 8-078-917-07 (Sheet 366) for material

needed.

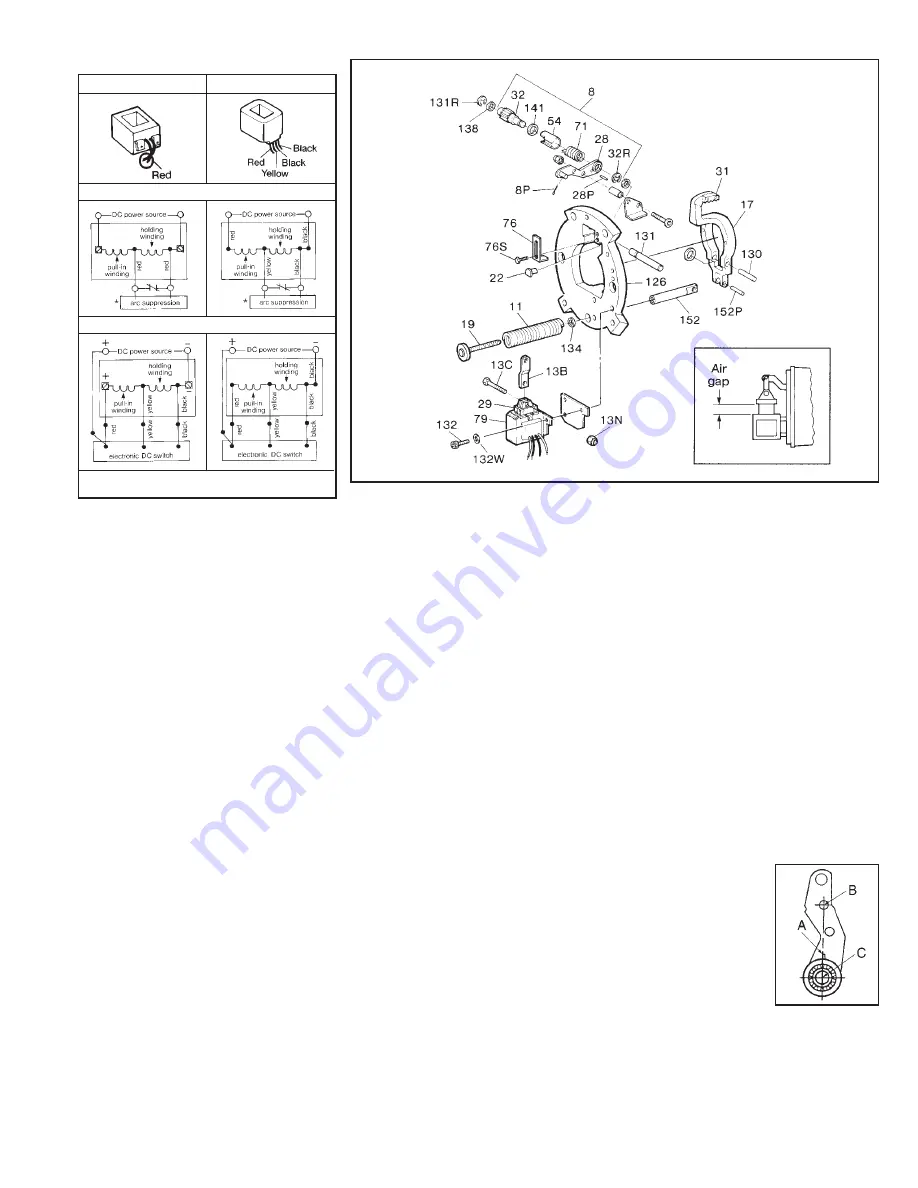

D. Self-adjust maintenance

(See Figure 6)

Since the self-adjust brake automatically

adjusts itself for friction disc wear, maintenance

is held to a minimum. The solenoid is factory

set with a 13/16” to 15/16” air gap, and

requires no resetting, even when changing

friction discs. The gap is determined by the

position of wrap spring stop (76). Should air

gap change, follow the steps listed below:

1. If (stop) screws (76S) had been loosened

and retightened, the air gap may require

resetting. The gap is measured between

mating surfaces of plunger (29) and solenoid

frame (79), and may be increased by raising

slightly, or decreased by lowering slightly,

wrap spring stop (76). Be sure to retighten

(stop) screws (76S). Manually lift plunger to

maximum travel and release. Depress

plunger, manually or electrically, and allow it

to snap up. Repeat several times, then

recheck air gap for factory setting of 13/16”

to 15/16”.

Note: To measure solenoid air gap on

vertically mounted brakes, grasp solenoid

link to hold plunger in a free horizontal

position and move toward solenoid frame

until spring pressure is felt. Holding firmly in

this position measure air gap between

mating (ground) surface on solenoid frame

and solenoid plunger. Adjust to proper gap

as directed in

Self-Adjust Maintenance.

Check gap by again holding plunger as

directed.

2. Tang of wrap spring (71) must be below, and

must make contact with, wrap spring stop

(76) when solenoid lever (28) is manually

raised. If stop is bent outward, allowing tang

to bypass it, rebend to square position,

assemble correctly, and reset solenoid air

gap as described in Paragraph 1.

3. Should air gap have decreased or

disappeared, the solenoid lever and pinion

assembly (8) may have become

contaminated due to lubrication or residue

as a result of overheating of brake. Cleaning

is required. Loosen pressure spring nut (19)

until pressure spring (11) is free. Remove

support plate assembly (142). Remove

cotter pin (8P) from solenoid lever (28) and

retaining ring (131R) from pivot pin (131).

Note location of spacer washer (138) if used,

and push pivot pin out to free affected

assembly. Remove retaining ring (32R) from

pinion (32) and disassemble. Parts should

be thoroughly cleaned in a clean solvent that

does not leave a film M.E.K. or equivalent.

Dry all parts thoroughly

and reassemble.

Rotate

pinion and wrap spring

clockwise until tang (A)

is aligned with

centerline of the upper

hole of the lever arm.

Refer to Figure 7.

Reassemble in reverse

order of Steps in this

Paragraph. Do not

retighten cap screw (19)

until support plate

assembly is mounted on endplate. Refer to

Steps H and I of

Installation Procedure

to

complete assembly.

4. Check condition and positioning of pinion

(32) and rack (part of lever arm assembly

Figure 6

DC Voltage Coil Connection

Figure 5

*Arc suppression used for coil above 48 Vdc.

**Follow polarity for switch to operate.

Electronic Switch**

(New Style)

Mechanical Switch

(Old Style)

Class B

Class H

Figure 7