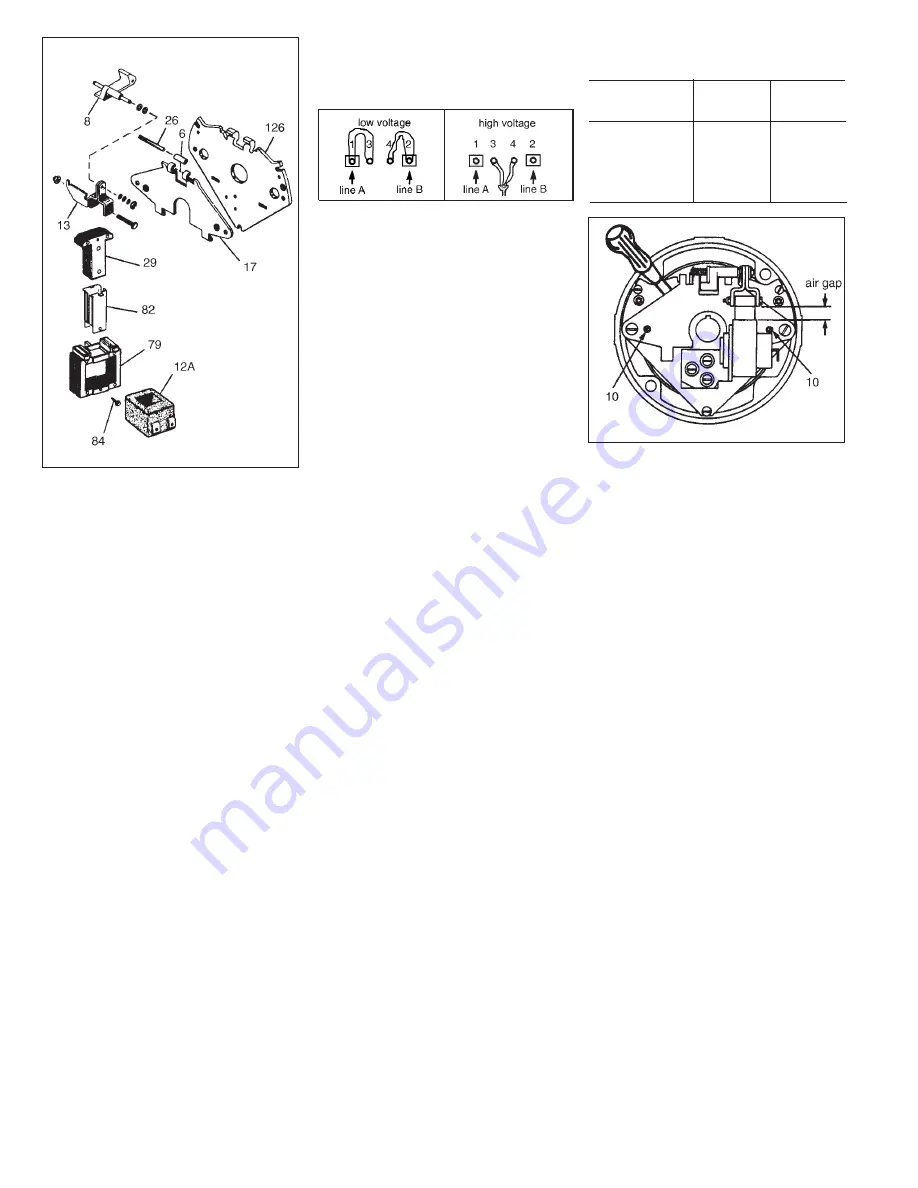

2. To replace the solenoid coil, disconnect

lead wire terminal screws (139S), lock

washers (139W) and lead wires (139).

3. Insert a screwdriver between support

plate (126) and top of lever arm (17).

With screwdriver wedge apart; remove

bearing pin (26) and solenoid lever (8)

with solenoid link (13) and plunger

(29). It is not necessary to separate

the solenoid lever, solenoid link and

plunger.

4. Remove plunger guide screw(s) (84).

Remove both plunger guides (82) by

prying up on the flanges. Discard

plunger guides.

5. Slide coil (12A) sideways from

solenoid frame (79). If necessary, tap

coil lightly with soft hammer. If coil had

burned out, be sure to remove all

foreign material from the solenoid

plunger (29) and solenoid frame (79).

6. Install new coil (12A) into solenoid

frame with same relative position as

old coil. Assemble new plunger guides

(82) and plunger guide screws(s) (84).

7. Low Voltage:

Jumper leadwire 3 to terminal 1

Jumper leadwire 4 to terminal 2

Incoming power to terminals 1 & 2

8. High Voltage:

Jumper leadwires 3 & 4 together

Incoming power to terminals 1 & 2

9. Be sure to check the following when

installing lead wires:

1) Must not be tight or pinched.

2)

Must not make contact with

friction disc.

3)

Must not be trapped between

solenoid plunger and frame.

10. Manually lift solenoid plunger to

maximum travel. Depress and allow

solenoid plunger to snap out several

times. Measure solenoid air gap

between mating surfaces of solenoid

frame and solenoid plunger. (On

vertically mounted brakes, it will be

necessary to push solenoid plunger

into solenoid frame to the point where

spring pressure is felt, before

measuring solenoid air gap.)

If solenoid air gap exceeds 11/16”,

adjustment is necessary.

The solenoid air gap measurements

are shown in Table in next column.

11. The solenoid air gap may be

decreased by turning both wear

adjustment screws (10) equal amounts

clockwise, approximately 1/8 turn, until

appropriate solenoid gap is attained.

To increase gap, turn screws

counterclockwise.

12. Reconnect coil leads.

13. Orient housing so that manual release

knob is approximately 20°

counterclockwise from vertical

centerline. Slide housing over

endplate register and rotate clockwise

to align bolt holes. Replace hardware

in reverse order of Step 1.

14.

Caution 1!

Do not run motor with

brake in manual release position. It is

intended only for emergency manual

movement of the driven load, not as a

substitute for full electrical release.

Caution 2!

Class H coils with

terminals. Do not bend lead wire

crimp connection as this causes

fatigue in the metal which may break

under vibration.

NOTE: For complete instructions,

with

troubleshooting

, request sheet

applicable to the series of brake that

you have.

Nominal Static

Torque (lb-ft)

65,000

Series

65,300

Series

1.5 and 3

13/32

13/32

6

13/32

13/32

10

1/2

1/2

15

9/16

9/16

Table: Solenoid Air Gap Measurement

(inches)

Copyright

©

1999-2006 by Rexnord Industries, LLC

Rexnord Industries, LLC, Stearns Division, 5150 S. International Dr., Cudahy, Wisconsin 53110, (414) 272-1100 Fax (414) 277-4364