Starke Arvid AB

Lyckåsvägen 3 Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

SE-459 30 Ljungskile

7

5.3. For use

•

Use equipment exclusively for lifting and moving materials with features as described in point 3.

•

Ensure the material to move has a weight that falls within the capacity indicated on the identification plate of the fork

and, obviously, that the material and the equipment fall within the capacity of the crane.

•

Important

. To correctly use the fork, it is indispensable to place a welded mesh chain between the crane hook and

the fork ring. The chain must have an upper end with a ring and the lower part with an entry closure hook. Ensure

the chain is suitable for the weight of the load supported, with multiple materials forked (Standards EN 814-4).

•

During operations using the fork, it must be grasped using your hands only using the specific handles.

To regulate point width, proceed as follows:

Mod. MB, MBA, MBCR, MBACR

-

With fork on the ground and without load, laterally push the neck until point slightly lifts, with the weight weighing on

the other point;

-

Use your heel to move the point slightly lifted outwards to the desired width;

-

To block the points, release the fork and screw the hand wheel situated on the upper part up to contrast;

-

To close, gradually unscrew the hand wheel and push the neck to the side. The points will slowly close until the fork

is released.

Mod. MBR MBR-A MBR-M MBRA-E ITA

-

With fork without load and lifted, loosen the wing screws placed over the sleeves on the base;

-

Regulate the width of the points and block them by screwing the wing screws in.

The MBR, MBR-A, MBR-M and MBRA-E models are also height adjustable; proceed as follows:

-

Connect the equipment to the crane as described in point 5.2 and rest it on the ground with no load;

-

Remove the through plug. The upper tube is free to slide on the lower one;

-

Lift the upper part of the fork with the crane to the desired height, corresponding to the perforations;

-

Block the fork by re-inserting the through plug and the safety stop.

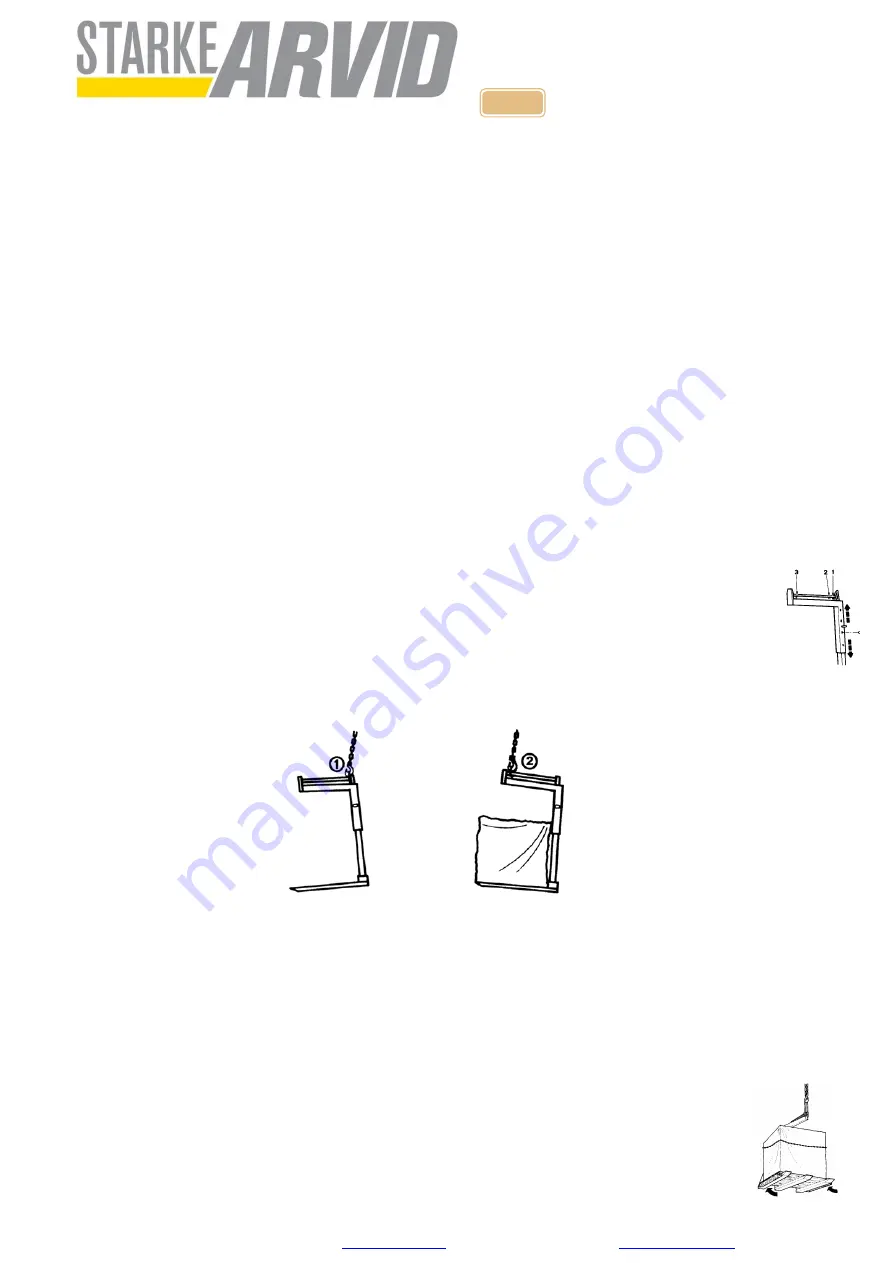

Positioning the ring on the different neck points (MBR

– MBCR - MBACR):

1) Fork slightly tilted forward to insert and remove pallet points more easily;

2) Balanced fork with full load.

•

The external points must be opened as much as possible based on the dimensions of the material moved and in any

case they must

always remain inside

the pallet cross-pieces.

•

To correctly lift materials remember that the centre of gravity of the pack lifted must coincide with that of the lifting

fork.

Non-compliance with this condition can cause:

-

The load to tip;

-

Overloading of the two teeth or worse, only one of the two.

•

The capacity indicated on the marking relates to the load uniformly distributed on both points.

•

Avoid moving the load using the end parts of the points.