– 3 –

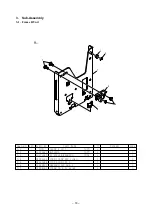

Screw

Board chassis

VR6

DIP Switch DSW1

3. Since it is adjusted by rotating the volume VR1, check the position of the volume. Prepare a small slotted

screwdriver.

4. Set the paper not for black mark.

5. Use the tip of a thin object to turn off the DIP switch DSW 1-4.

6. Turn the power on.

7. Rotate the volume VR1 using micro screwdriver, to adjust it to a position whereat both the LED1 (green LED) and

the LED2 (red LED) lamps light.

8. Turn the power OFF.

9. Turn the DIP switch DSW 1-4 to its original setting of ON.

This completes the paper end & black mark sensor adjustment.

2.

Adjustment of the Paper Near End Sensor

1. Turn the printer off and unplug the power cord.

2. Remove the screws. Then, remove the board chassis.

Fig. 1-3 Adjustment Volume

Summary of Contents for TUP900 Series

Page 1: ...THERMAL PRINTER TUP900 SERIES TECHNICAL MANUAL SECOND EDITION ...

Page 11: ... 9 Fig 2 2 Lubricated Areas TMP942 B 1 2 4 5 5 2 3 4 B C C D D A A ...

Page 12: ... 10 Fig 2 3 Lubricated Areas PR921 B B C 7 C A A 7 8 8 6 ...

Page 18: ... 16 B TUP942 11 2 10 5 11 12 12 13 4 6 12 ...

Page 34: ... 32 2 5 Flash Flash EPSON BA T500 Compatible Manufacturer molex ...

Page 35: ... 33 3 5 ...

Page 36: ... 34 4 5 Pitch Thermistor ...

Page 37: ... 35 5 5 ...

Page 45: ... 43 8 Serial Interface Board 25pin 8 1 Circuit Diagram ...

Page 47: ... 45 9 Serial Interface Board 9pin 9 1 Circuit Diagram ...

Page 49: ... 47 10 USB Interface Board 10 1 Circuit Diagram ...

Page 51: ... 49 11 Parallel Interface Board 11 1 Circuit Diagram ...