BR87 User

Manual ◄ 11

NOTE:

Partially depressing the trigger allows the tool to run

at slow speed. Slow-speed operation permits easier

starting of the tool bit into the work surface.

5. To start, break an opening (hole) in the center of the

surface. After making a hole, break portions of the

material into the original opening. For best produc-

tivity, the breaking should be done around the origi-

nal hole.

The size of the broken material will vary with the

strength and thickness of the base material and the

amount of any reinforcement wire or rebar.

Harder material or more reinforcing wire or rebar will

require taking smaller bites. To determine the most

effective bite, start with 2 in. / 50 mm or smaller bites.

Bites can then be gradually increased until the bro-

ken piece becomes too large, requiring increased

time to break off the piece.

Sticking of the tool bit occurs when too large a bite is

being taken and the tool bit hammers into the mate-

rial without the material fracturing. This causes the

tool bit to become trapped in the surrounding mate-

rial.

6. The underwater model requires preventative main-

tenance after each day’s use underwater and prior

to being placed in storage. See the General Service

Notes section in this manual for this maintenance

procedure.

COLD WEATHER OPERATION

If the breaker is to be used during cold weather, preheat

the hydraulic fluid at low engine speed. When using the

normally recommended fluid, fluid temperature should

be at or above 50 °F/10 °C (400 ssu/82 centistokes) be-

fore use.

Damage to the hydraulic system or breaker can result

from use with fluid that is too viscous or thick.

The recommended hose size is .500 inch/12 mm I.D. up

to 50 ft/15 m long and .625 inch/16 mm I.D. minimum up

to 100 ft/30 m.

PRE-OPERATION PROCEDURES

CHECK POWER SOURCE

1.

Using a calibrated flowmeter and pressure gauge,

check that the hydraulic power source develops a

flow of 7-9 gpm/26-34 lpm at 1500-2000 psi/105-

140 bar.

2. Make certain the hydraulic power source is equipped

with a relief valve set to open at 2100-2250 psi/145-

155 bar maximum.

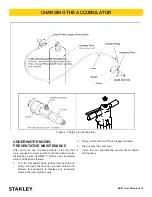

INSTALL TOOL BIT

1. Rotate the latch on the breaker foot downward

(pointing away from the tool).

2. Insert the tool bit into the foot and pull the latch up to

lock the tool bit in place.

CONNECT HOSES

1. Wipe all hose couplers with a clean, lint-free cloth

before making connections.

2. Connect the hoses from the hydraulic power source

to the tool fittings or quick disconnects. It is a good

practice to connect return hoses first and discon

-

nect them last to minimize or avoid trapped pressure

within the tool.

3.

Observe flow indicators stamped on hose couplers

to ensure that fluid flow is in the proper direction.

The female coupler on the tool hose is the inlet cou-

pler.

4. Move the hydraulic circuit control valve to the ON

position to operate the tool.

NOTE:

If uncoupled hoses are left in the sun, pressure in-

crease within the hoses may make them difficult to

connect. When possible, connect the free ends of

the hoses together.

OPERATION PROCEDURES

1. Observe all safety precautions.

2. Install the appropriate tool bit for the job.

3.

Place the bit firmly on the surface to be broken.

4. Squeeze the trigger to start the breaker. Adequate

down pressure is very important. When the tool bit

breaks through the obstruction or becomes bound,

release the trigger and reposition the tool bit.

OPERATION