(6)

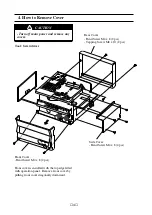

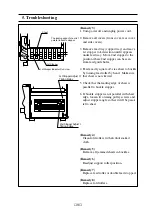

Support Plate

Deflector

Frame Hole

2nd Drive Roller

The clearance is 0.9〜1.3mm

(0.03" to 0.06") and parallel.

Bush Plate

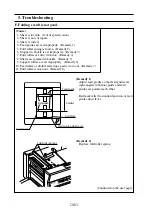

Smooth Movement

Fulcrum

Lubrication

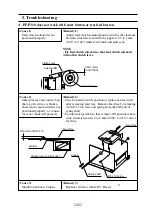

5. Troubleshooting

B. Sheets is not folded correctly with single fold.

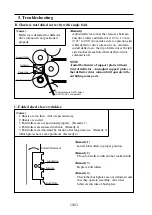

C. Folded sheets have wrinkles.

(Cause)

1. Sheets are too thin. (Out of specification)

2. Sheets are curled.

3. Fold rollers are not positioned properly. (Remedy 1)

4. Fold rollers are smeared with ink. (Remedy 2)

5. Fold rollers are deformed by friction after long time use. (Remedy 3)

6.Bush plates have some problems. (Remedy 4)

(Remedy 1)

Install fold rollers in proper position.

(Remedy 2)

Clean fold rollers with alcohol soaked cloth.

(Remedy 3)

Replace fold rollers.

(Remedy 4)

Check that bush plates are not deformed and

that they operate smoothly. After that

lubricate fulcrum of bush plate.

(Cause)

Deflector is deformed or deflector

drive solenoid is not positioned

properly.

(Remedy)

Adjust deflector so that the clearance between

2nd drive roller and deflector is 0.9 to 1.3 mm

(0.03" to 0.06") from drive side to operation side

while deflector drive solenoid is on. And also

install deflector so that tip of deflector at the left

side touches frame hole while deflector drive

solenoid is off.

NOTE

- Install both sides of support plates without

twist of deflector. And adjust support plate so

that deflector drive solenoid will operate with-

out hitting some parts.