1. Description

The Stahl Tools DSDS Soldering & Desoldering Station is a high-performance and multi-function station developed by Stahl

Tools to use in electronic product research, production, and rework. This tool is used in the fields of electronic research,

teaching and production, especially for repairing and reworking electronic appliances and communication equipment.

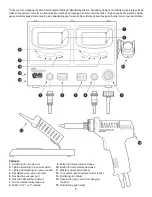

1.1 Control Unit

The soldering iron and the desoldering gun are controlled automatically by two micro-processors. The digital control

electronics, high-quality sensor and heat exchange system guarantee precise temperature control at the soldering tip. The

highest degree of temperature precision and optimal dynamic thermal behavior under load conditions is obtained by the

quick and accurate recording of the measured values in a closed control circuit. This design works especially well with lead-

free production techniques.

1.2 Soldering Iron

Soldering iron is 60W and offers a wide spectrum of optional soldering tips that can be used anywhere in the electronics field.

The high power and slim design makes this iron suitable for fine soldering work. The heating element is made of PTC and

the sensor on the soldering tip controls the soldering temperature quickly and accurately.

1.3 Desoldering Gun

Desoldering gun with a power of 80W has three optional tip sizes that can be used anywhere in the electronics field.

The high power and gun type design makes this iron suitable for fine desoldering work. The heating element is made of PTC

and the sensor on the desoldering tip controls the desoldering temperature quickly and accurately.

2. Technical Specification

Rated voltage range 110-130V AC 60Hz; rated power input 160W.

3. Operating Instruction

Place the soldering and desoldering guns in their holders separately. Then connect the plug to the receptacle on the station

and turn clockwise to tighten the plug nut. Check that the power switch is on the “OFF” position. Connect the control unit

to the power supply and switch on the power. Then a self-test is carried out in which all display elements are switched on

briefly. The electronic system then switches on automatically to the set temperature and displays this value.

Adjust the temperature and wait for the gun’s current read-out to reach the desired heat setting. Apply the tip of the soldering

gun to the solder joint and squeeze the trigger as soon as the solder melts.

3.1 Display and Temperature Setting

The digital display:

1.

Shows the actual temperature of the tip.

2.

Shows the setting temperature. Press the UP

or DOWN button to set the digital display to

the desired heat setting. The set-point can be

changed for ±1

°

C by tapping the UP or DOWN

button. Holding the button down will change the

set-point quickly. The digital display will return

automatically to the actual value and the iron

heats up quickly to the desired setting.

3.

°

C/

°

F display: Switching the temperature display

from

°

C to

°

F by pressing the “

°

C/

°

F” button and

then the electronic system will display the actual

temperature

(1)

and setting temperature

(2)

in

°

F,

and vice versa.

4.

When the actual temperature on the soldering tip is less than the set-point, “HEAT ON” will display when the tip is heating

up to maintain the desired temperature.

5.

When the absolute offset is more than ±10

°

C between the actual temperature and the set-point on the soldering tip or

the nozzle, “WAIT” will display. This means that the temperature control system detects a non-stable situation. Pause for

a moment until “WAIT” disappears.

6.

When “ERROR” displays, there may be an issue with the temperature control system, or the soldering iron is not

connected to the control system correctly.

4