5

4.

Auxiliary Equipment

UK

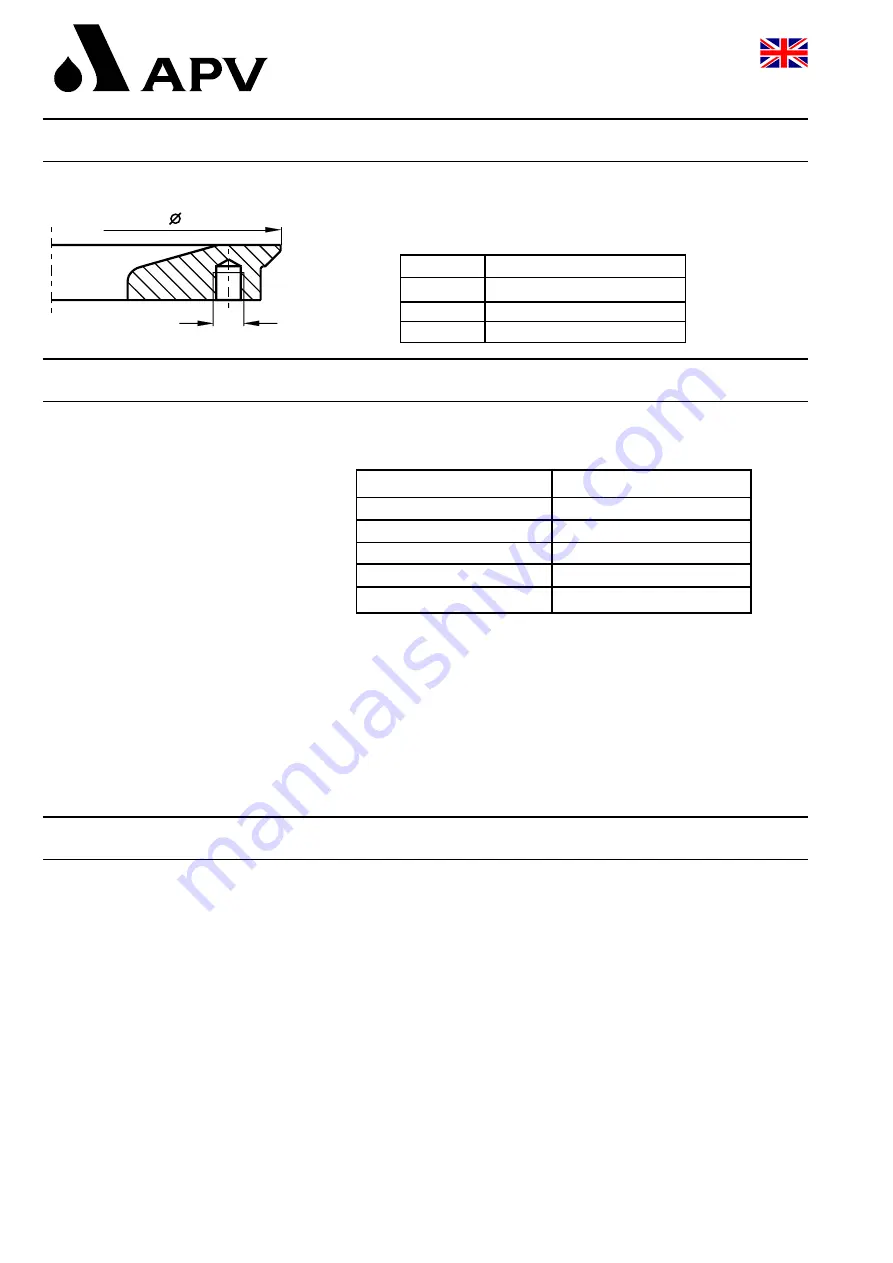

The tank bottom welding flange for the DKRT2 valve

does not form part of the scope of supply.

Order reference numbers for the tank bottom welding flange:

5.

Cleaning

Cleaning recommendation for the DKR valve

in the beverage industry

-

The flushing times refer to a cleaning pressure of p = 3 - 5 bar.

-

The flushing times indicated for the individual cleaning steps are

standard values. In specific applications these times must be

adjusted depending on the product, the pressure ratio and the

degree of soiling.

-

The flushing quantity per CIP spraying cycle amounts to

about 1 litre at a cleaning pressure of 3 - 5 bar.

6.

Installation

-

The valve must be installed in horizontal position at the tank bottom.

Fluids and operating leakages are, therefore, freely drainable to the

bottom and the leakage chamber drains off.

-

With several valves being parallely connected with one pipeline,

a passage of the operating leakage to the cleaning connection of

adjacent valves must be avoided.

Installation of a shut-off device or a check valve in front of the

cleaning connection is required.

-

Cleaning connection with hose 8 x 1.

-

Attention:

Observe welding instructions.

cleaning step

CIP - spraying

pre - flushing

2 x 10 sec.

caustic flushing 80° C

3 x 10 sec.

intermediate flushing

2 x 10 sec.

acid flushing

3 x 10 sec.

subsequent flushing

2 x 10 sec.

tank bottom welding flange

C

M10

DN

ref.-No.:

50

31B 31 - 08 - 030/47

80

31B

3

1 - 08 - 032/47

100

31B

3

1 - 08 - 034/47

Double - Seat Ball Valve DELTA DKRT 2

Tank Outlet Valve

Operating Manual : Rev. 4