34

Disassembly and assembly

CRL/EN (1810) 2.2

7.8

Mechanical seal

7.8.1

Instructions for mounting a cartridge seal

➢

First read the following instructions regarding mounting a cartridge seal. Follow these

instructions closely when mounting a cartridge seal.

• This mechanical seal comes as a ’full cartridge seal’. This means that this mechanical

seal must be mounted as one single piece and that it shall NOT be taken apart!

• A cartridge seal is a fragile precision instrument. Leave the cartridge seal in its original

packing until you are ready to mount it!

• Clean all receiving parts properly. Make sure your hands and working environment are

clean!

7.8.2

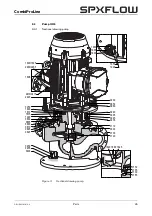

Disassembling a cartridge seal

1 Remove the guard (0276).

2 Re-fit the centering tabs on the cover of the seal cartridge into the groove in the seal

collar in order to immobilise the cartridge seal.

3 Disassemble the impeller, see paragraph 7.7.1 "Disassembling the impeller".

4 Remove the nuts (1810) and washers (1805) and pull the seal cartridge backwards.

5 Remove the bolts (0850) and washer (0855) and knock the pump cover loose from

the bearing bracket (OH3) or lantern piece (OH5).

6 Pull the entire seal cartridge from the shaft.

7.8.3

Mounting a cartridge seal

1 OH3: Put the bearing bracket in upright position (impeller side up).

OH5: Place the electric motor with the shaft upright.

2 Push the seal cartridge onto the shaft.

3 OH3: Mount the pump cover (0110) in the correct position in the fitting edge of the

bearing bracket (2100). OH5: Mount the pump cover (0110) in the correct position

in the fitting edge of the lantern piece (0250).

Check whether the pump cover is

at right angles to the shaft

. Place washers (0855) fasten the pump cover with

bolts (0850).

4 Mount the seal cartridge to the pump cover (0110). Check the position in view of the

connection points. Place washers (0805) fasten the seal cartridge with nuts (0810).

5 Fit the impeller and other parts, see paragraph 7.7.2 "Mounting the impeller" and

paragraph 7.5.2 "Assembling the Top Pull Out unit OH3" or paragraph 7.6.2

"Assembly Top Pull Out unit OH5".

6 Release the centering tabs of the seal cartridge, turn them halfway round and secure

them again against the seal cover. The shaft must now be able to rotate freely.

7 Place the guard (0276).

Summary of Contents for Johnson Pump CombiProLine OH3

Page 2: ......

Page 4: ...2 EC EN 1712 6 0 ...

Page 6: ...4 INT EN 1512 1 2 ...

Page 10: ...8 CRL EN 1810 2 2 ...

Page 20: ...18 General CRL EN 1810 2 2 ...

Page 40: ...38 Dimensions CRL EN 1810 2 2 ...

Page 52: ...50 Parts CRL EN 1810 2 2 ...

Page 66: ...64 ORDFORM 1512 3 3 EN ...