AA

19

0D

AG

Ser

ies

Air

Motor

‐

Driven

Tank

Washer

|

0

8/

1

5/

20

11

|

RE

V

.

1

15

7. Inspect O-Rings inside the upper shaft seal body

sub-assembly (4) and seals inside pinion gear

bushing retainer sub-assembly (22).

8. If damaged or worn, replace with new sub-

assemblies.

9. Remove any foreign material from gear teeth of the

pinion gear bushing retainer sub-assembly (22)

before reassembly.

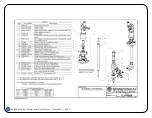

REASSEMBLY OF THE UNIT (SEE PARTS LIST PL 190DAG & PL 190DAGH)

1. Install one new bushing (23) into the lower end of

the rotary Y-housing (14) and one new bushing (13)

onto the stem (12) up to shoulder.

2. Slide the rotary Y-housing (14) and bushing (23)

back onto the stem (12).

3. Reassemble the pinion gear bushing retainer sub-

assembly (22) onto shaft (10) by slowly rotating it as

you slide it onto the shaft.

This procedure will help

prevent damage to the shaft seals inside.

Also, be

sure the nozzle hub gear assembly (14) and pinion

gear bushing retainer sub-assembly (22) mesh

properly.

4. Torque pinion gear bushing retainer sub-assembly

(22) to 40 lb-ft (54 Nm).

5. Replace the drive plate (21) and lower screw shield

(20).

6. The bottom of the shaft should pass through the

drive link so it is about flush with the bottom of the

drive link.

7. Apply Loctite 243 or 242 to threads of hex head cap

screw (19) and thread into shaft (10).

8. Holding the rotary Y-housing (14), torque hex head

cap screw (19) to 5 lb-ft (7 Nm).

9. Install gasket (5) onto shaft (10) at the upper end of

the shaft.

10. Apply Loctite 243 or 242 to threads of the upper

shaft seal body sub-assembly (4) and reassemble

onto shaft (10) by slowly rotating it as you slide it

onto the shaft.

11. This procedure will help prevent damage to the

shaft seals inside.

12. Torque upper shaft seal body sub-assembly (4) to

50 lb-ft (68 Nm).

13. Complete the reassembly by installing the groove

pin (9) into shaft (10).

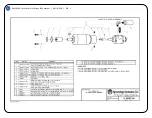

REPLACEMENT OF #46340 AIR MOTOR DRIVE (SEE PARTS LIST DRAWING PL 46340-190)

1. If it is not already attached, align the keyway on the

coupling (5) with the key (6) on the gear motor sub-

assembly (11) shaft and lightly tap the coupling (5)

until it bottoms on the shaft.

2. Insert the coupling (5) through the hole in the top of

the 190 inlet casting.

3. The slot on the coupling (5) should be aligned and

indexed over the groove pin and drive shaft on the

190 assembly.

4. The air motor drive assembly can now be rotated

until the through holes on inlet body align with the

M5 female threaded inlet holes on the air motor

drive assembly.

5.

Using a 4 mm hex Allen wrench, secure the gear

motor sub-assembly (11) to the inlet body using two

M5 bolts (1) and spring lock washers(2).

6.

BEFORE RE-INSTALLING IN A TANK,

CONNECT AN AIR LINE TO THE AIR MOTOR

DRIVE TO MAKE SURE THE UNIT WORKS

PROPERLY.