IM-P184-09

CMGT Issue 4

14

start of text under grey section header box

start of text continuing from previous page

TRANSLATION RUN OVER

6.6 How to fit the stem and bellows assembly

By following through Section 6.5 it is now possible to fit a new stem/bellows assembly (

6, 5

):

-

Fitting this is opposite to removal - remembering to fit a bellows collar gasket (

11a

) between the bellows

support collar and valve bonnet (

2

).

-

Ensure the bellows collar gasket (11a) is accurately located. Before fitting the new stem/bellows assembly

(

6 and 5

) into the bonnet (

2

).

-

Apply a small amount of lubricating compound such as Gulf Sovereign LC grease to the end of the stem

pin (which is pressed into the stem).

-

Ensure the stem pin is aligned with the slot inside the bonnet.

-

Carefully slide the stem up through the bonnet.

-

Before screwing the end of the stem into the bonnet bush remember to fit a new stem packing ring (

8

)

(see Section 6.5), the original gland washer (or gland follower) and gland nut (or gland flange) over the

stem (

6

). Do not allow the stem thread to damage the inner surface of the gland packing ring (

8

).

-

Carefully slide the new packing ring (

8

) down the stem into the cavity and slide the original gland washer

(or gland follower if fitted) on top of the packing ring (

8

).

-

After the valve has been fully assembled remember to create a safe seal between the gland packing

ring (

8

) and the stem (

6

) by tightening down the gland nut to the recommended tightening torque (see

Table 1).

6.7 How to fit the disc

By following through Section 6.5 it is now possible to replace the valve’s disc:

-

To replace the disc (

4

) simply remove the old stem pin and replace the disc (

4

).

-

Attach the new disc with the new stem pin (supplied). Where the disc (

4

) is attached using a retaining

nut and collet arrangement, simply prise the crimped skirt away from the retaining nut and unscrew.

Remove the collets remembering to save these and the retaining nut as they are not supplied as spares.

Fitting is the opposite to removal but ensure the collets and threads are lightly greased with lubricating

compound such as Molybdenum Sulphide.

-

If a new disc is being fitted then crimp the collet retaining nut securely across two corners by deforming

the disc’s thin metal skirt. If the original disc is being fitted then re-crimp using a fresh part of the skirt.

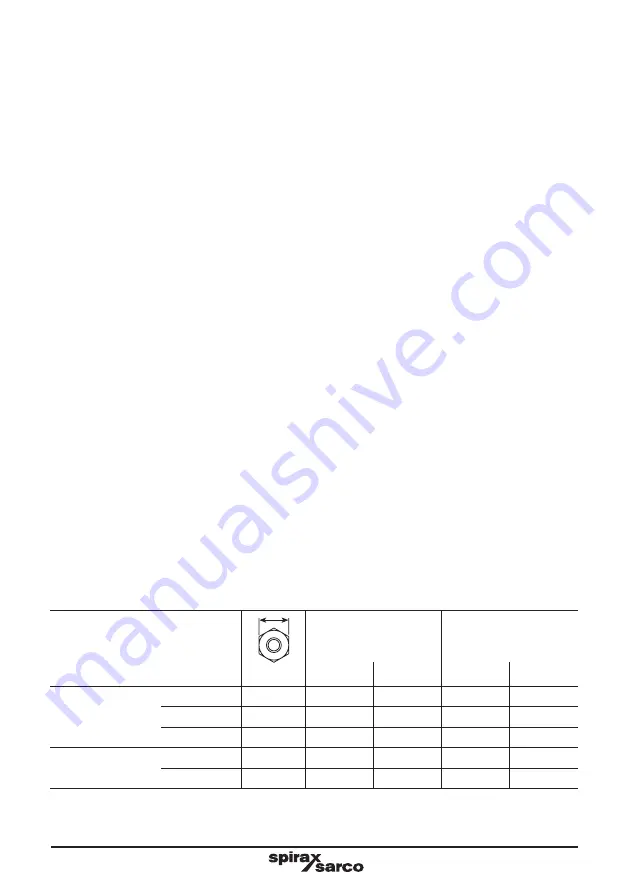

Table 1 Recommended tightening torques

Item

Size

PN40

ANSI 300

mm

N m

(lbf ft)

N m

(lbf ft)

Bonnet bolts and

nuts (9 & 10)

DN15 - DN25

17 A/F

35 - 40

(26 - 29)

50 - 55

(36 - 40)

DN40 - DN65

19 A/F

55 - 60

(40 - 44)

85 - 90

(63 - 66)

DN80 - DN100

24 A/F

130 - 140

(95 - 103)

190 - 200

(140 - 147)

Gland nut

DN15 - DN80

22 A/F

5 - 10

( 3.5 - 7)

5 - 10

( 3.5 - 7)

DN100

32 A/F

15 - 20

(10.5 - 14 )

15 - 20

(10.5 - 14)