-34-

For Machines Mfd. Since 12/20

South Bend Tools

Model SB1112

TROUBLESHOOTING

Ram does not

move.

1.

Hydraulic pump OFF.

1.

Verify START button has been pressed and WORK

LAMP light is ON.

2.

Pressure set too low for task.

2.

Adjust pressure valve to appropriate PSI for

operation (Page 27).

3.

Hydraulic oil level too low.

3.

Fill hydraulic tank to proper level (Page 19).

4.

Obstruction in hydraulic line.

4.

Check hydraulic lines for obstructions.

5.

Motor coupler at fault.

5.

Access coupler and tighten/replace.

6.

Hydraulic pump at fault.

6.

Replace hydraulic pump.

7.

Pressure adjustment valve at fault.

7.

Replace pressure adjustment valve.

8.

Hydraulic ram at fault.

8.

Replace hydraulic ram.

9.

Motor at fault.

9.

Replace motor.

10.

Hydraulic pump at fault.

10.

Replace hydraulic pump.

Ram moves

slowly or applies

insufficient

pressure.

1.

Pressure set too low for task.

1.

Adjust pressure adjustment valve to appropriate

PSI for operation (Page 27).

2.

Hydraulic system leaking.

2.

Locate source of leak and repair/replace leaking

part.

3.

Hydraulic filter clogged.

3.

Replace hydraulic filter.

4.

Obstruction in hydraulic line.

4.

Check hydraulic lines for obstructions.

5.

Pressure adjustment valve at fault.

5.

Replace pressure adjustment valve.

6.

Ram direction valve at fault.

6.

Replace ram direction valve.

7.

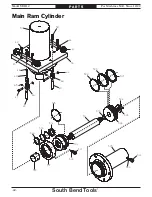

Ram seals at fault.

7.

Replace ram seals.

8.

Motor at fault.

8.

Replace motor.

9.

Hydraulic pump at fault.

9.

Test/replace hydraulic pump.

Ram moves

erratically.

1.

Air present in hydraulic system.

1.

Bleed hydraulic system (Page 32).

2.

Hydraulic oil level too low.

2.

Fill hydraulic tank to proper level (Page 19).

3.

Hydraulic system leaking.

3.

Locate source of leak and repair/replace leaking

part.

4.

Hydraulic oil contaminated.

4.

Drain and replace hydraulic oil (Page 32).

Symptom

Possible Cause

Possible Solution

Motor operates in

reverse.

1.

Motor is wired out of phase.

1.

Swap two incoming power leads (Page 36).