46

RCD-W10

4-6. VWDC Check

1)

Select the menu as follows. Control

→

Macro, and select 06vwdc_S.ttl.

Press “Open”.

2)

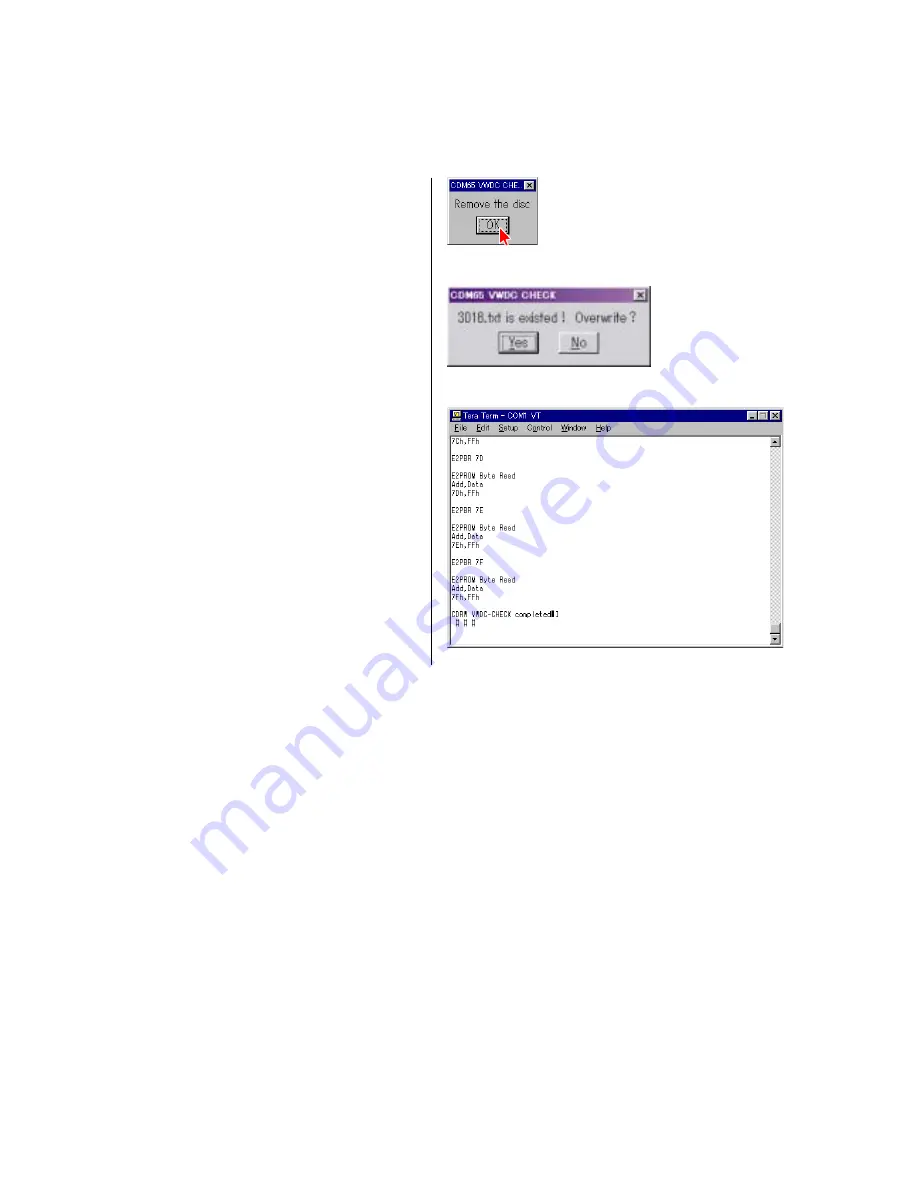

As prompted by the message shown in Fig. 4-51, remove the

disc from the tray and press “OK”.

3)

Because this step saves the result of electrical adjustment in a

file, there can be a case that the dialog as shown in Fig. 4-52

appears.

When you want to overwrite ..................... Press “Yes”.

When you want to create a new file .......... Press “No”.

4)

Check that the message “CDRW VWDC-CHECK completed!”

appears.

(Fig. 4-53)

NG Judgment Result Indication

4

Fig. 4-51

4

Fig. 4-52

4

Fig. 4-53

4-6-1.

EEPROM Write NG!

Contents : This message appears when writing data into EEPROM fails.

Measure : When the steps of 01ldp_S.ttl through 05cdrw_S.ttl have no problem and the error occurs only in this step, it is assumed that

an error has occurred momentarily in the interface between PC and CDM65. Therefore, repeat execution of 06vwdc_S.ttl

again.

4-6-2.

VWDC judge [Line Top - End] [NG]

Contents : This message appears when the VWDC value is outside the specification.

Measure : It is assumed that the optical laser unit has deteriorated. If this error occurs after the KRM-220CAA is replaced, the adjustment

error in the step of 01ldp_S.ttl is assumed. Therefore, repeat execution of steps of 01ldp_S.ttl through 05cdrw_S.ttl again. In

the cases other than above, check if the laser power adjustment is correctly performed or not, using LDPtestL_S.ttl.

Summary of Contents for RCD-W10 - Cd/cdr Recorder/player

Page 17: ...17 RCD W10 MEMO ...

Page 52: ...52 RCD W10 MEMO ...