2-6

FWD-50PX2

2-5. Flash Down-loading Method

Preparation

1.

Connect this unit with PC using the RS-232C cable.

2.

Disconnect the AC power cord of this unit.

Download

1.

Start the file, “FWD50PX2_Down.exe”.

2.

Select “COM1” as COM Port and “57600” as baud

rate as below picture.

3.

Click the

[Port|Setup]

, then click the

[OK]

button.

4.

Click the

[Load]

button, then select the file from the

designated folder.

5.

Click the

[Run|DownLoad]

button.

Download is started. (Down Load Time : about 5

minutes)

If down load is finished, the monitor will be re-booted

automatically.

m

.

Do not remove AC cord from PC and monitor while

down load operation is being proceeded.

.

After processing micom update with ISP program,

please execute following in order for the unit to

maintain “Shipping default condition”.

*

Execute EXCEPT WB in INITIALIZATION.

*

Execute COPY WB DATA in WB DEFAULT

DATA.

*

Execute INIT GOODS in FOR TEST.

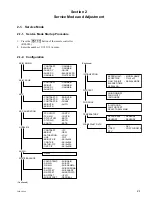

2-6. DEVICEINFO Section

1.

Connect PC to PDP using the serial cable.

2.

Set the port.

(1) Select the model. (FWD-50PX2)

(2) Select the port. (COM1, COM2, COM3 or COM4)

n

The initial setting is COM1.

3.

Click the

[Read]

button in “Model Name”.

(Data reading)

If the data reading is completed successfully, the

setting in the port that has been selected in step 2 can

be performed. If not, return to step 2 and select another

port. Then, perform the data reading again.

4.

Data writing

Modify: Model name, serial number, operating time

Write:

Model name, serial number, operating time

Summary of Contents for FWD-50PX2

Page 6: ......

Page 46: ......

Page 48: ...Printed in Japan Sony Corporation 2006 1 22 2006 FWD 50PX2 SY E 9 878 387 01 ...