GRW

Installation

7

SolutionAirGroup.com

|

GRW - Manual

8. Fuses are furnished and installed by the factory in

accordance with the National Electrical Code, ANSI/

NFPA 70, and /or the Canadian Electrical Code, CSA

C22.1. If replacement of any fusing is necessary, the

replacement MUST be of the same amperage as the

original. Failure to use equivalent replacement fuses

may result in damage to components within the

electrical system of the unit and/or the building. If any

of the original wires need to be replaced, they must

be replaced with type TEW 105° or equivalent except

where noted.

9. On units with three-phase power supplies, make sure

that motor rotation is correct as connected.

Auxiliary Power Connections

A separate 120/1/60 power supply may be required on

units with convenience outlets and lights. Refer to unit

wiring diagrams for wiring sizing details and connection

points.

Control Installation

All field wiring must be in accordance with local codes, or

in the absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, and/or the Canadian Electrical Code,

CSA C22.1.

Control wiring will depend on the controls provided with

the unit. A controller is provided with the unit unless

otherwise specified in the submittal documents. Refer to

unit electrical wiring diagrams for details.

Control Connections

Units supplied with controllers may require field-wiring to

a remote sensor or control panel. Refer to unit electrical

wiring diagrams for details.

An optional space thermostat or sensor may be shipped

loose for field installation. The sensor may be duct

mounted and/or wall mounted.

1. Locate space sensors or thermostats where they

will provide a representative reading of the space

condition.

2. Avoid areas with cold drafts or in the warm supply-air

stream of the unit.

3. On indoor units, do not mount the thermostat or

sensor on the unit casing, as it may be affected by heat

radiating off the unit.

4. Do not place near other sources of warmth, such as

lamps, appliances, etc.

5. Refer to unit electrical wiring diagrams for details on

how to wire the sensor to the control panel.

6. Ensure that all remote wiring is equivalent to factory

installed wiring and that voltage drop does not exceed

10 percent.

An optional duct mounted discharge air temperature

sensor may be shipped loose for field installation.

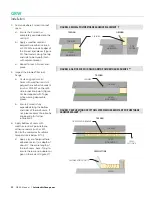

1. The sensor strip must be parallel to the flow of air.

2. The sensor must be mounted as close to the center of

the duct as possible.

3. The sensor must be located in a straight section of the

duct and must be 8-10 feet (2.4 to 3m) downstream

from the supply air connection.

4. Do not install temperature sensors near any elbows or

transitions.

5. Refer to unit electrical wiring diagrams for details on

how to wire the sensor to the control panel.

6. Ensure that all remote wiring is equivalent to factory

installed wiring and that voltage drop does not exceed

10 percent.

An optional remote control panel may be shipped loose for

field installation.

7. Locate the indoor panel where operation and

maintenance personnel have ready access.

8. Follow the manufacturer’s installation instructions.

9. Refer to unit electrical wiring diagrams for details on

how to wire the sensor to the control panel.

10. Ensure that all remote wiring is equivalent to factory

installed wiring and that voltage drop does not exceed

10 percent.

Where possible, the low limit temperature sensor is factory

mounted. Some unit configurations require the sensor

to be field mounted in the supply air ductwork. In this

situation, the sensor and field wiring will be coiled up in the

weather housing. The installing contractor shall install the

sensor approximately 10 ft. (3 m) down the supply air duct.