6

Section 2 - OPERATING INSTRUCTIONS

2.1 PRE-START CHECK LIST

Make the following checks and perform the service

required before each start-up.

2.1.1. Check tires and add or release air as needed

to bring pressure to 12 psi in front and 12 psi in rear

tires.

2.1.2. Check guards, deflectors and covers to make

sure all are in place and securely tightened.

2.1.3. Check engine oil and add oil as needed to

bring level up to the FULL mark. Refer to engine

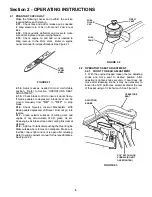

owner’s manual for oil specifications. See Figure 2.1.

FIGURE 2.1

2.1.4. Adjust seat as needed to most comfortable

position. Refer to Section “OPERATOR’S SEAT

ADJUSTMENT”.

2.1.5. Check blade control to insure it works freely.

If blade pedals are depressed, blade lever can be

moved manually from “ON” to “OFF” to stop

blade.

2.1.6. Check Reverse Lockout Mechanism. With

blade pedals depressed, shift lever must not go into

reverse.

2.1.7. Clean exterior surfaces of cutting deck and

engine of any accumulation of dirt, grass, oil, etc.

Keep engine air intake screen and cooling fins clear at

all times.

2.1.8. Add fuel to tank after pushing the Rear Engine

Rider outside where fumes can dissipate. Make sure

fuel filler cap is tight and vent is open after refueling.

Refer to engine owner’s manual for fuel specifications.

See Figure 2.2.

FIGURE 2.2

2.2 OPERATOR’S SEAT ADJUSTMENT

2.2.1. FRONT TO REAR ADJUSTMENT

1. With the engine stopped, loosen the two adjusting

knobs and move seat to desired position. After

adjustment, tighten knobs securely. If seat does not

move after loosening knobs, it may be necessary to

loosen the 5/16” patch lock screws located at the rear

of the seat using a 1/2 inch wrench. See Figure 2.3.

FIGURE 2.3

SAFE

LEVEL

AREA

FUEL

FILLER

CAP

OPEN

VENT

FUEL

TANK

ADJUSTING

KNOBS

OPERATOR’S

SEAT

5/16” PATCH LOCK

SCREWS (DO NOT

OVERTIGHTEN)

Summary of Contents for WM301021BE

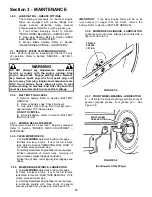

Page 32: ...32 PRIMARY MAINTENANCE ...

Page 33: ...33 PRIMARY MAINTENANCE ...

Page 34: ...34 PRIMARY MAINTENANCE ...

Page 35: ...35 PRIMARY MAINTENANCE ...