17

Section 4 – ADJUSTMENT & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance or

service with the engine or blades running. STOP

blades. STOP engine. Set brake. Remove key.

Remove spark plug wire from spark plug and secure

wire away from spark plug. Engine and components

can be extremely hot. Avoid burns by allowing engine

and components sufficient time to cool.

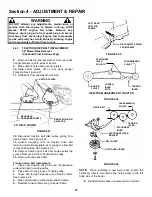

4.2.4. MOWER DECK ADJUSTMENT (LEVELNESS)

FRONT-To-REAR

(42”

Decks)

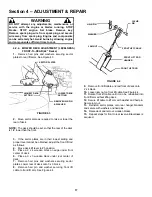

1. Remove hair pins and washers securing sector

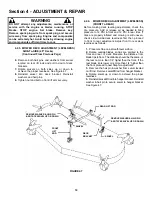

plates to rear lift arms. See Figure 4.3.

FIGURE 4.3

2. Move sector plate as required to raise or lower the

rear of deck.

NOTE: The deck should be set so that the rear of the deck

is 1/4” lower than the front.

3. If the sector plates are in their lowest setting and

proper level cannot be obtained, adjust the front lift rod

as follows:

4. Move deck lift lever to #5 position.

5. Place a 2 x 4 wooden block on edge under front

center of deck.

6. Place a 3 x 3 wooden block under rear center of

deck.

7. Remove hair pins and washers securing sector

plates. Lower rear of deck onto 3 x 3 block.

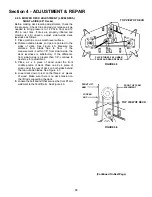

8. Remove hair pin and washer securing front lift

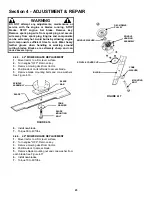

cable to front lift arm. See Figure 4.4.

FIGURE 4.4

9. Remove front lift cable and rest front of deck onto

2 x 4 block.

10. Loosen jam nut on front lift cable. See Figure 4.4.

11. Rotate front lift cable until it can be reinstalled into

front lift arm without lifting deck.

12. Secure lift cable to lift arm with washer and hair pin.

Secure jam nut.

13. Reinstall sector plates onto rear hanger brackets

and secure with washers and hair pins.

14. Raise deck and remove wooden blocks.

15. Repeat steps for front to rear level until levelness is

acquired.

SECTOR PLATES

HIGHEST DECK

SETTING

REMOVE HAIR PIN

& WASHER

LOWEST DECK

SETTING

FRONT LIFT ROD

WASHER

HAIR PIN

JAM NUT

FRONT LIFT CABLE

CLEVIS

PIN

FRONT LIFT ROD

HANGER

Summary of Contents for WLT160H42GBV

Page 34: ...34 SECTION 5 ELECTRICAL SYSTEM ...

Page 39: ...39 PRIMARY MAINTENANCE ...

Page 40: ...40 PRIMARY MAINTENANCE ...

Page 41: ...41 PRIMARY MAINTENANCE ...

Page 42: ...42 PRIMARY MAINTENANCE ...