18

Section 4 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any adjustments, maintenance,

service or repairs with the engine running. Stop engine.

Stop blade. Engage parking brake. Remove key.

Remove spark plug wire from spark plug and secure

away from plug. Engine and components are HOT.

Avoid serious burns; allow all parts to cool before

working on machine. Fuel Filler Cap and Vent must be

closed securely to prevent fuel spillage.

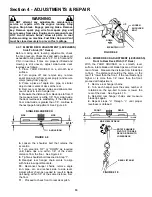

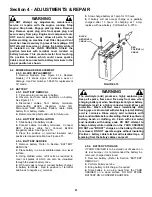

4.3.5. BLADE BRAKE ADJUSTMENT

The SNAPPER YARD CRUISER is equipped with

an electric clutch/brake that should stop blade

rotation in 5 seconds or less after being turned off.

If blades continue to rotate longer than 5 seconds,

adjustment or replacement is required. When

properly adjusted, a .010” to .012” feeler gauge will

fit thru the three inspection slots located on the side

of the clutch as shown. See Figure 4.5. Excessive

clearance can adversely affect the function of the

clutch and produce blade stop times over 5

seconds. To adjust, turn the three adjusting nuts

clockwise to reduce clearance. The clearance at

each of the three slots must be set the same.

FIGURE 4.5

WARNING

Blades must stop rotating in 5 seconds or less after

blades have been turned off. DO NOT operate

machine until blade brake has been adjusted or

repaired and is functioning properly. Contact your

SNAPPER dealer for assistance.

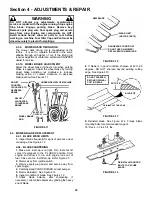

4.3.6. ADJUSTING MOWER BLADE

The straightness of the mower blade(s) is essential

for smooth, even mowing. Adjust blade straightness

as follows.

1. Make sure fuel cap is on tight. Turn fuel shut off

valve (If equipped) to the “CLOSED” position. Start

engine and allow it to run until engine runs out of

fuel. Close vent on fuel filler cap. Refer Figure 2.3.

2. Remove key from ignition switch.

3. Remove spark plug wire(s) and secure away

from spark plug(s).

4. Carefully stand YARD CRUISER on rear bumper.

5. Select a point on the deck and mark for reference.

6. Mark blade tips as “A” and “B”.

7. Rotate blade until blade tip “A” is at deck

reference mark.

8. Measure the distance between deck lip and

blade tip. NOTE: On 33” decks, the measurement

between the blade tip and deck lip should be 3/8”.

See Figure 4.6.

9. Repeat step 8 with blade tip “B”.

10. If measurement between blade tips and deck are

different and there is more than 1/16” difference

between blade tip measurements, adjust blade as

follows:

a. Loosen jam-nuts on the ends of blade bar.

b. Adjust jackscrews “IN” or “OUT” until blade

tip measurements are within 1/16” of each other

and blade tips are 3/8” away from deck lip. See

Figure 4.7.

c. Retighten jam-nuts securely.

FIGURE 4.6

FIGURE 4.7

ADJUSTING

NUT (3)

INSPECTION

SLOT (3)

.010” TO .012”

FEELER

BLADE TIP

3/8”

DECK LIP

MARK

BLADE

ENDS

3/8” FROM BLADE

TIP TO OUTER DECK

LIP

JACKSCREWS

JAM NUTS

Summary of Contents for EYZ15334BVE

Page 27: ...28 PRIMARY MAINTENANCE...

Page 28: ...29 PRIMARY MAINTENANCE...

Page 29: ...30 PRIMARY MAINTENANCE...

Page 30: ...31 PRIMARY MAINTENANCE...