25

Maintenance

Driven Disc Replacement (Continued)

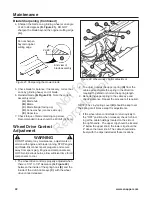

2. Using needle nose pliers, unhook the drive spring

(A, Figure 29)

and slide the driven disc assembly

off the hex shaft.

3. Remove the two snap rings

(A, Figure 30)

which

secure the rubber driven disc

(B)

to the driven disc

assembly.

4. Install a new rubber driven disc onto the driven

disc assembly, and secure with the retaining rings.

5. Reverse the above procedures for reassembly and

installation of the driven disc assembly.

A

Figure 29: Removing the driven disc assembly

Driven Disc Bearing Replacement

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

!

!

IMPORTANT:

The bearing on these machines is

staked into the thrust plate. The bearing will have to be

driven out with a mallet and a large punch. A new bear-

ing with four retaining screws will have to be purchased

to replace existing bearing.

If the driven disc bearing requires replacement, replace

the bearing as follows:

1. Remove the driven disc assembly. Refer to the

Section entitled “Driven Disc Replacement”.

2. Remove both snap rings

(A, Figure 30)

that

secure the rubber driven disc

(B)

to the thrust

plate.

3. Slide the rubber driven disc hub out of the bearing.

4. Drive out the existing bearing

(C)

.

5. Install a new bearing and secure to the thrust plate

with four retaining screws. Tighten the screws

securely.

6. Reassemble the components in reverse order.

NOTE:

Be sure to replace the shim washer

(D)

when

reassembling the driven disc assembly.

A

Figure 30: Replacing the driven disc

B

D

C

en

Not

for

Reproduction