5

5.2

WELDING ALUMINIUM

The welder must be prepared as for welding mild steel

with gas protection, but with the following differences:

- 100% ARGON as the shielding gas for welding.

- A wire having a composition suited to the base material

to be welded.

For welding ALLUMAN: 3÷5% silicon wire

- For welding ANTICORODAL: 3÷5% silicon wire

- For welding PERALUMAN: 5% magnesium wire

- For welding ERGAL: 5% magnesium wire

Use grinding wheels and brushes specifically designed

for aluminium, and never use them on other materials.

REMEMBER that cleanliness is quality!

The wire reels must be stored in nylon bags with dehu-

midifying packets.

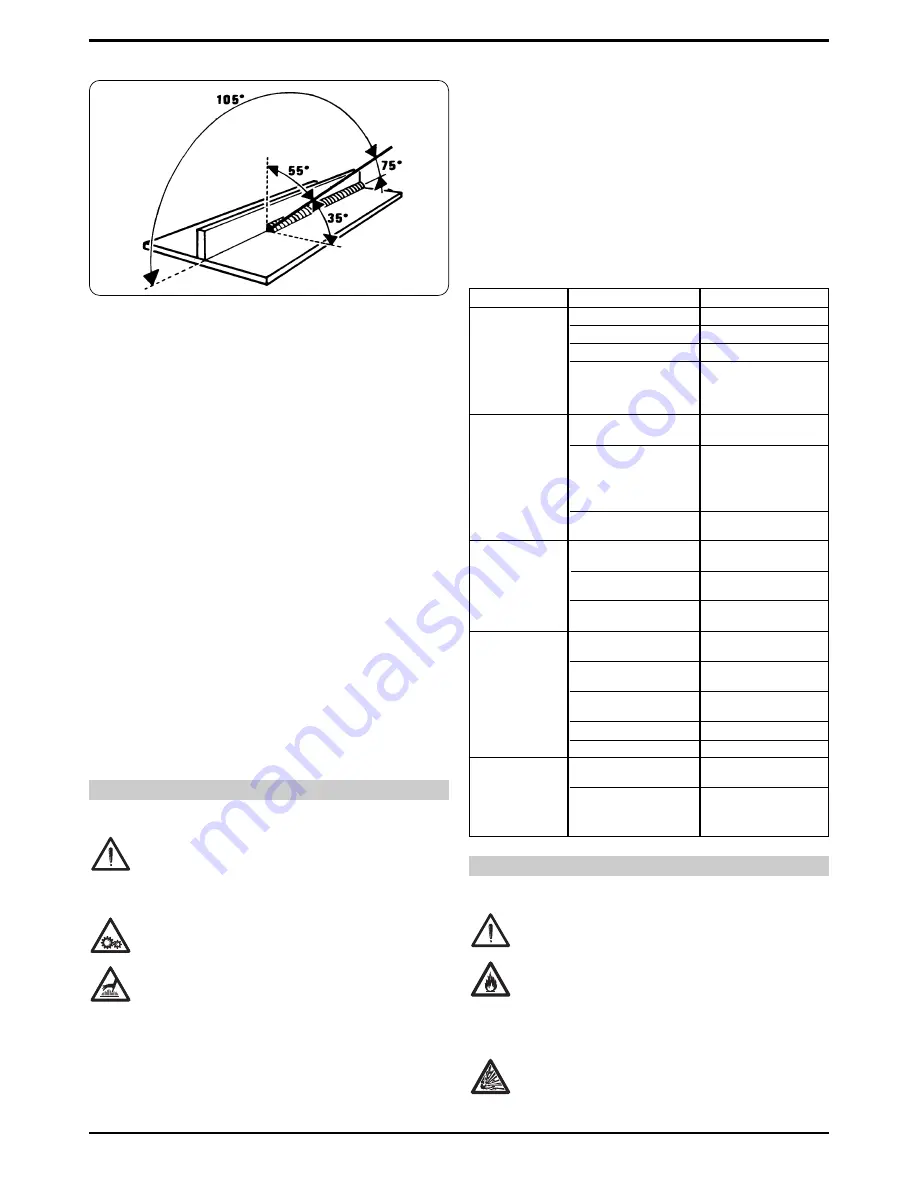

For the correct welding angle see figure 3.

5.3 WELDING STAINLESS STEEL

The welder must be prepared as for welding mild steel

with gas protection, but with the following differences:

- Reel of stainless steel wire compatible with the compo-

sition of the material to be welded.

- Cylinder containing 98% ARGON + 2% 02 (recom-

mended composition)

The recommended torch angle and welding direction are

shown in figure 3.

6 MAINTENANCE AND CHECKS

6.1

GENERAL NOTES

WARNING!

Turn off the welder and unplug the power cord from the

socket before each checking and maintenance operation.

Moving parts can cause serious injuries.

Keep away from moving parts.

GLOWING HOT SURFACES can cause serious

burns.

Let the unit cool before servicing.

Periodically remove any dust or foreign matter that may

have deposited on the transformer or diodes; to do so,

use a jet of clean, dry air.

When replacing the wire roller, make sure the groove is

aligned with the wire and corresponds to the diameter of

the wire used.

Always keep the interior of the gas nozzle clean to avoid

metal bridges created by welding dross between the gas

nozzle and the contact tip. Make sure the outlet hole of

the contact tip has not expanded excessively; if so,

replace.

Strictly avoid striking the torch or allowing it to suffer

violent impact.

6.2 TROUBLESHOOTING GUIDE

7 SAFETY PRECAUTIONS

7.1 FIRE

WARNING!

Avoid causing fire because of sparks, slag, hot

metal or pieces.

Make sure that suitable fire-fighting equipment

is available close to welding area.

Remove all flammable and combustible material from

the welding area and its surrounding (32 ft minimum).

Do not weld containers of combustible or flam

mable material, even when empty.

Fig. 3

TROUBLE

The welding machi-

ne supplies limited

current

Welding with a lot

of metal spatter

The wire jams or

entangles between

the drive rolls and

the torch infeed wire

guide

No wire feed or irre-

gular wire feed

Porosity in the wel-

ding seam

PROBABLE CAUSE

Line fuse blown

Burnt out diode or diodes

Burnt out electronic board

Loose torch or ground

connections or any other

electrical power connec-

tions

Voltage adjustment switch

has a loose contact

Improper adjustment of

welding parameters

Poor ground connection

Contact tip with wrong dia-

meter

Misalignment of the drive

roll groove

Obstructed or clogged

liner

Drive roll with too large a

groove

Obstructed or clogged

liner

Wire holding roller not

completely tightened

Clogged contact tip

Insufficient shielding gas

Excess oxidation of the

edges to be welded

Gas nozzle partially or

completely clogged by

spatter

REMEDY

Replace line fuse

Replace

Replace

Tighten all connections

Replace the switch

Select the correct parame-

ters through the welding-

voltage switch and the

wire-speed adjustment

potentiometer

Check grounding connec-

tions

Replace

Realign

Remove and clean

Replace the drive roll

Remove and clean

Tighten all the way

Replace

Increase gas delivery

Thoroughly clean the

edges with a metal brush

Remove and clean or

replace being careful not

to clog the gas outlets