MIXING INSTRUCTIONS

Use only top quality paint. Inferior paint voids SMITHCO warranty.

1. Completely follow mixing instructions on paint container.

2. Never use mixed paint without straining.

3. The depth of the color of the line will be determined by percentage of water added to the

paint. In most cases, the mix should be at least 2 parts water to 1 part paint.

NEVER

use

more than 50% paint.

4. Use spraying nozzle TeeJet 8002VS tip only. These tips have been tested and work best

with the SMITHCO pumping system.

5. Fill tank with the desired amount of water.

6. Start unit and turn the paint pump on, increase engine rmp, thus starting agitation.

7. Pour the strained paint into the tank slowly to properly mix.

MAINTENANCE INSTRUCTIONS

NOTE: IF MACHINE IS TO BE LEFT MORE THAN ONE HOUR, SYSTEM SHOULD BE

FLUSHED. DO NOT LEAVE PAINT IN SYSTEM OVER NIGHT.

1.

After each day’s use, follow instructions below.

A. Open the gate valve, located at the rear of the tank. Drain remaining paint into a

resealable container using the hose provided. Drain and replace the strainer.

B. Flush the paint tank with fresh water for 5 minutes with the drain valve open until all

the paint residue is out of the tank.

C. Close the ball valve at the bottom of the tank. Connect the hose from the gate valve

to a clean water source.

D.

Turn the selector valve to “Flush”.

E. Start the engine, turn on the paint pump.

F. Turn on the water.

G. Turn on the spray switch. Flush tips until the water flows clear.

H. Turn off the water, disconnect the hose. Open the ball valve and drain the tank

again. Drain the strainer again also.

I. Remove spray tips from both booms. Clean thoroughly using a soft bristle brush and

soapy water.

2. Lubricate the following:

A. Steering shaft bearings.

B. Hub bearings.

C. Both boom arms.

D. Front axles.

3. See engine manual for maintenance instructions on the engine.

4. When storing the unit after the painting season, the battery should be disconnected.

5. For winter storage, the unit and nozzle tips must be thoroughly cleaned and flushed.

6. System requires 10W40 Oil.

4

Summary of Contents for SLN270

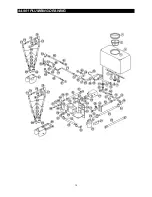

Page 8: ...44 901 MAIN FRAME DRAWING 6 ...

Page 11: ...44 901 ENGINE PUMP DRAWING 9 ...

Page 13: ...44 901 STEERING DRAWING 11 ...

Page 15: ...44 901 HYDRAULIC HOSE DIAGRAM 13 ...

Page 17: ...44 901 PLUMBING DRAWING 15 ...

Page 20: ...44 901 FRAME TANK DRAWING 18 ...

Page 22: ...SUPER LINER WIRING DIAGRAM 20 ...

Page 27: ......