Z_ISE3-TF2Z043EN

Page 2 of 3

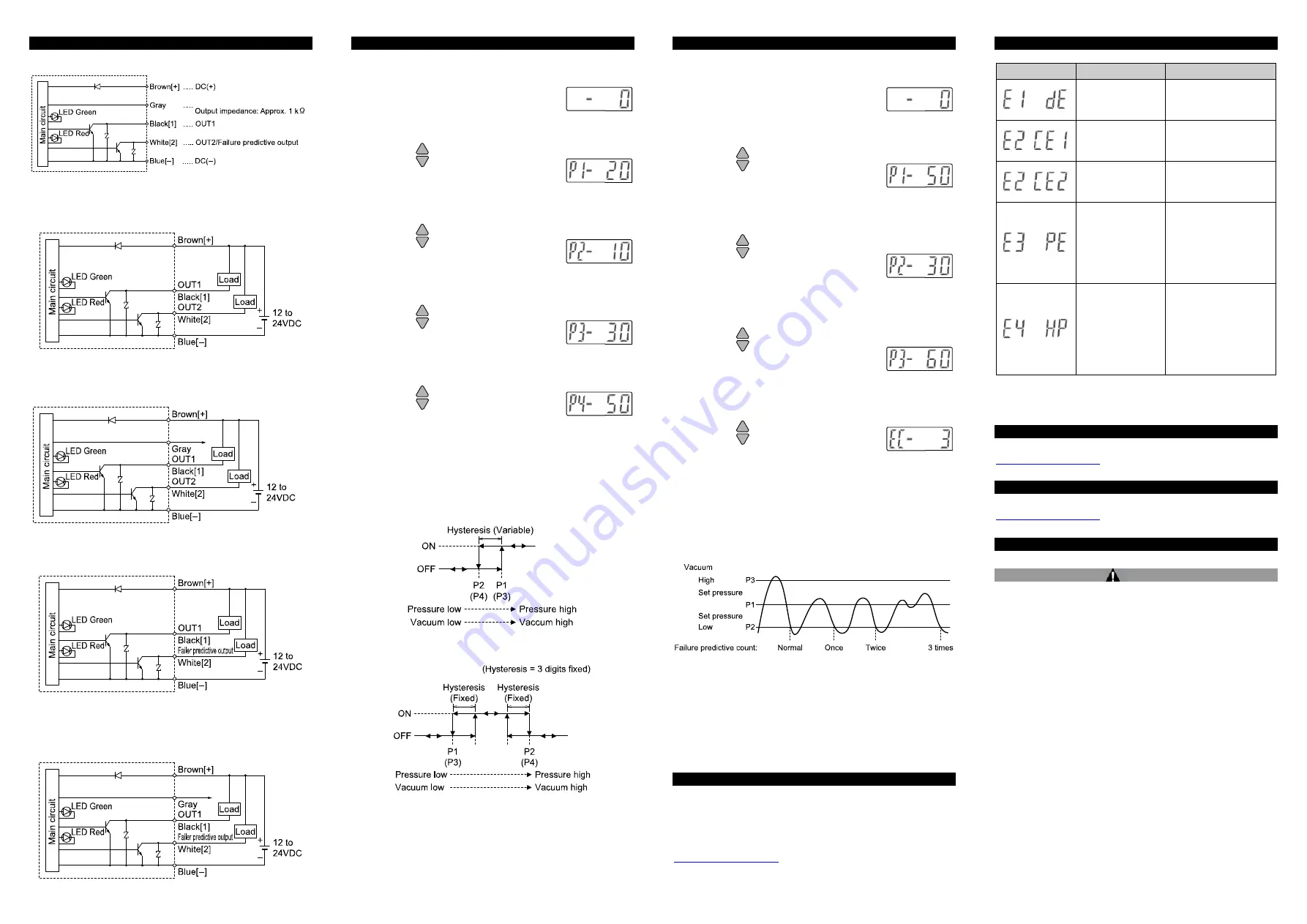

5 Wiring (continued)

5.3 Wiring diagram

5.4 Internal circuit and wiring

ZSE3 / ISE3(L)-#-21

Switch output, NPN open collector output, 2 outputs, Max. 30 V, 80 mA

ZSE3 / ISE3(L)-#-22

Switch output, NPN open collector output, 2 outputs, Max. 30 V, 80 mA

Analogue output: 1 to 5 V, Output impedance: Approx. 1 k

Ω

ZSE3 / ISE3(L)-#-23

Switch output, NPN open collector output, 1 output, Max. 30 V, 80 mA

Failure predictive output, NPN open collector output, 1 output.

ZSE3 / ISE3(L)-#-24

Switch output, NPN open collector output, 1 output, Max. 30 V, 80 mA

Failure predictive output, NPN open collector output, 1 output.

Analogue output: 1 to 5 V, Output impedance: Approx. 1 k

Ω

6 Pressure Setting

6.1 2 output type

6.2 Output method

•

Hysteresis mode (P1

≥

P2, P3

≥

P4)

•

Window comparator mode (P1

<

P2, P3

<

P4)

•

Hysteresis mode (same as for positive pressure use) When the value

of hysteresis is set to 2 digits or less, the switching output might chatter

due to fluctuation of the input pressure around its set point.

•

Window comparator mode (same as for positive pressure use) since

the hysteresis will be 3 digits, separate P1 from P2 (in case of 2-output

type, same as for P3 and P4) by 7 digits or more.

* 1 digit is the minimum pressure display unit.

6 Pressure Setting (continued)

6.3 1 Output type with Failure Predictive function

6.4 Failure Predictive function

The failure predictive detection counter is incremented when the switch

is turned on then is turned off, without the pressure (exceeding P1) not

reaching the failure predictive pressure (P3).

The failure predictive detection output is energized when the set failure

predictive counter (EC) is incremented consecutively. When the switch is

turned ON and the pressure (exceeding P1) exceeds the failure

predictive pressure (P3), the failure predictive counter is reset.

(This example shows a case in the hysteresis mode).

7 Other Settings

•

Peak Hold mode

•

Bottom Hold mode

•

RESET button function

•

Zero clear function

Refer to the operation manual available on the SMC website (URL:

8 Error Indication

Error Display

Error Type

Troubleshooting Method

The set data has

been changed

under some

influences.

Press the RESET button

and set all data again.

Load of OUT1 has

short-circuited and

overcurrent is

flowing.

Turn off the power supply

and replace the load

connected to the OUT1

(black wire).

Load of OUT2 has

short-circuited and

overcurrent is

flowing.

Turn off the power supply

and replace the load

connected to the OUT2

(white wire).

Pressure exceeding

0.5 MPa has been

applied.

(In case of positive

pressure, pressure

exceeding the rated

pressure has been

applied.)

Lower the pressure to 0.5

MPa or less. (In case of

positive pressure, lower

the pressure to the rated

pressure or less.)

Compared with the

ambient pressure

-0.07 MPa (in case

of 1 MPa use) or -7

kPa or more (in

case of vacuum use

or 100 kPa use) has

been applied during

zero clear.

After adjusting the

pressure to the ambient

pressure, perform RESET

operation.

If the error cannot be reset after the above measures are taken, then

please contact SMC.

9 How to Order

Refer to the operation manual on the SMC website (URL:

) for How to order information.

10 Outline Dimensions

Refer to the operation manual or catalogue on the SMC website (URL:

) for Outline Dimensions.

11 Maintenance

11.1 General Maintenance

Caution

•

Not following proper maintenance procedures could cause the product

to malfunction and lead to equipment damage.

•

If handled improperly, compressed air can be dangerous.

•

Maintenance of pneumatic systems should be performed only by

qualified personnel.

•

Before performing maintenance, turn off the power supply and be sure

to cut off the supply pressure. Confirm that the air is released to

atmosphere.

•

After installation and maintenance, apply operating pressure and

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

•

If any electrical connections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

•

Do not make any modification to the product.

•

Do not disassemble the product, unless required by installation or

maintenance instructions.

How to reset the product after power cut or forcible de-energizing

The setting of the product is remained as that before power cut or de-

energizing. The output condition is also basically recovered to that before

power cut or de-energizing, but may change depending on the operating

environment. Therefore, check the safety of whole facility before

operating the product. If the facility is under accurate control, wait until

the product has warmed up (approx. 10 minutes).

1. Set value input mode

Press the "SET" button to display "P1-20"

*1

.

The output OUT1(1) set value input mode is

selected.

*1: If the set value of P1 is -20.

2. OUT1(1) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the output OUT1(2) set value input mode.

The set value of P2 is displayed.

3. OUT1(2) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the output OUT1(1) set value input mode.

The set value of P3 is displayed.

4. OUT2(1) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the output OUT2(2) set value input mode.

The set value of P4 is displayed.

5. OUT2(2) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

exit this mode.

P1: Set value for OUT1(1)

P2: Set value for OUT1(2)

P3: Set value for OUT2(1)

P4: Set value for OUT2(2)

1. Set value input mode

Press the "SET" button to display "P1-50"

*1

.

The output OUT1(1) set value input mode is

selected.

*1: If the set value of P1 is -50.

2. OUT1(1) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the output OUT1(2) set value input mode.

The set value of P2 is displayed.

3. OUT1(2) set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the failure predictive pressure set value

input mode.

The failure predictive set value is displayed.

4. Failure predictive pressure set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

select the failure predictive count set value input

mode.

The failure predictive count set value is displayed.

5. Failure predictive count set value input

Pressing the

button increases the set value.

Pressing the

button decreases the set value.

Press the "SET" button to save the set value and

exit this mode.

P1: Set value for OUT1(1)

P2: Set value for OUT1(2)

P3: Set value for failure predictive pressure.

EC: Set value for failure predictive count.

Analogue output: 1 to 5 V (

±

5%F.S.)

Analogue output

Analogue output