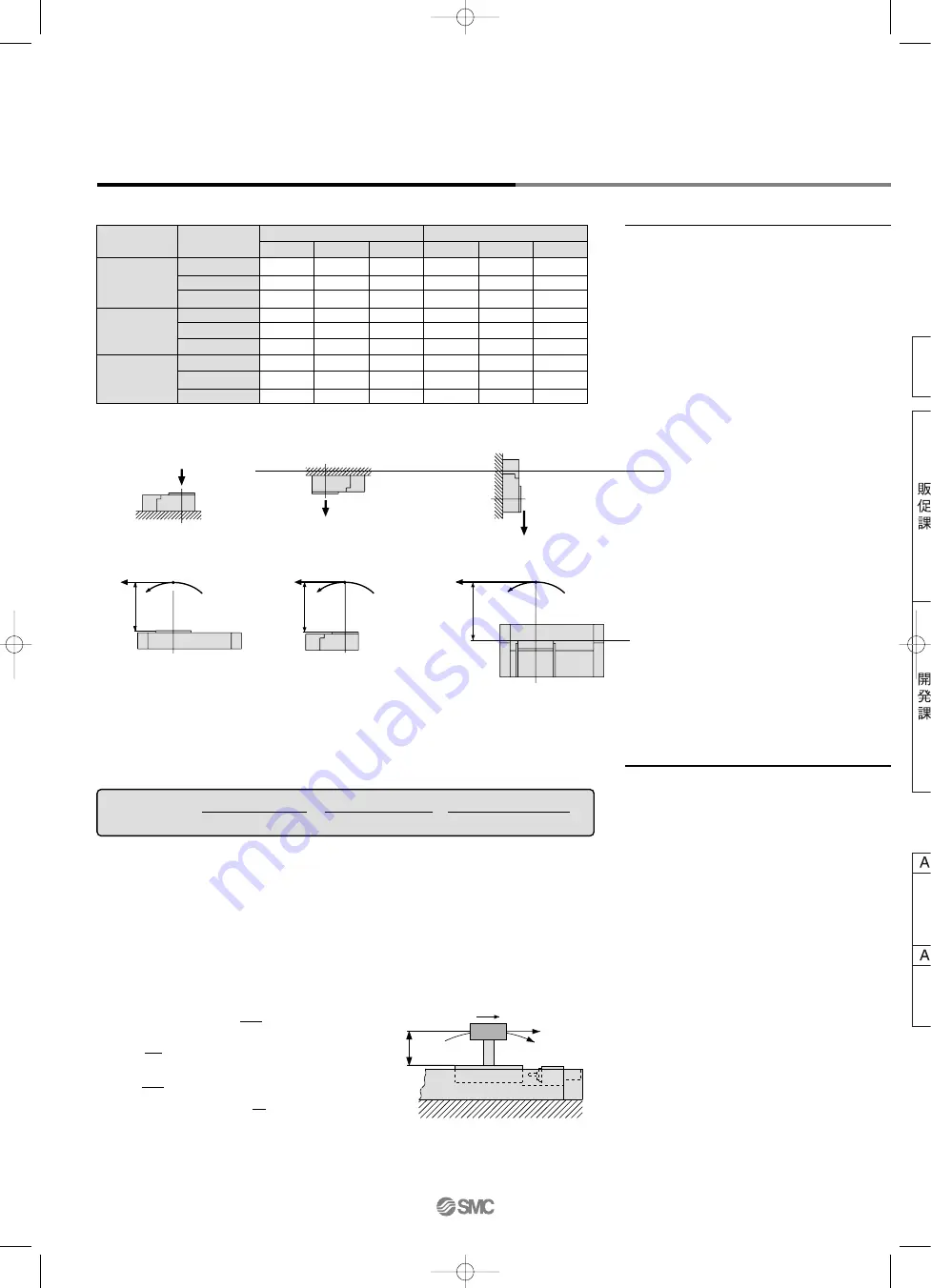

Maximum Allowable Moment/Maximum Load Mass

Model

MY2H

MY2C

MY2HT

Bore size

(mm)

16

25

40

16

25

40

16

25

40

Maximum allowable moment (N

⋅

m)

M

1

5

13

45

7

28

60

46

100

200

M

2

4

14

33

6

26

50

55

120

220

M

3

3.5

10

28

7

26

60

46

100

200

Maximum load mass (kg)

m

1

18

35

68

15

32

62

20

38

80

m

2

16

35

66

13

30

62

18

35

80

m

3

14

30

57

13

30

62

18

35

80

Maximum Allowable Moment

Select the moment from within the range of

operating limits shown in the graphs. Note

that the maximum load mass value may

sometimes be exceeded even within the

operating limits shown in the graphs.

Therefore, also check the allowable load for

the selected conditions.

Maximum Load Mass

Select the load mass from within the range

of limits shown in the graphs. Note that the

maximum allowable moment value may

sometimes be exceeded even within the

operating limits shown in the graphs.

Therefore, also check the allowable

moment for the selected conditions.

Moment (N

⋅

m)

Load mass (kg)

<

Calculation of guide load factor>

M

1

= F

1

x L

1

F

1

L

1

F

2

L

2

M

2

= F

2

x L

2

m

2

L

3

M

3

= F

3

x L

3

F

3

m

3

m

1

F

E

M

E

υ

m

L

1

The above values are the maximum allowable values for moment and load. Refer to each graph regarding the maximum

allowable moment and maximum load mass for a particular piston speed.

1. Maximum load mass (1), static moment (2), and dynamic moment (3) (at the time of impact with

stopper) must be examined for the selection calculations.

∗

To evaluate, use

υ

a (average speed) for (1) and (2), and

υ

(impact speed

υ

= 1.4

υ

a) for (3).

Calculate m max for (1) from the maximum load mass graph (m

1

, m

2

, m

3

) and Mmax for (2) and (3) from the maximum

allowable moment graph (M

1

, M

2

, M

3

).

Sum of guide

load factors

Σ

α =

Load mass

[

m

]

Maximum load mass

[

m max]

Static moment

[

M]

(1)

Allowable static moment

[

Mmax]

Dynamic moment

[

M

E

]

(2)

Allowable dynamic moment

[

M

E

max]

Note 1) Moment caused by the load, etc., with cylinder in resting condition.

Note 2) Moment caused by the impact load equivalent at the stroke end (at the time of impact with stopper).

Note 3) Depending on the shape of the workpiece, multiple moments may occur. When this happens, the sum of the load

factors (

Σ

α

) is the total of all such moments.

2. Reference formulas [Dynamic moment at impact]

Use the following formulas to calculate dynamic moment when taking stopper impact into consideration.

m

F

F

E

υ

a

M

1.4

υ

=

1.4

υ

a (mm/s) F

E

=

υ

a

⋅

g

⋅

m

Note 4)

100

1

∴

M

E

=

⋅

F

E

⋅

L

1

= 0.05

υ

a m L

1

(N

⋅

m)

Note 5)

3

Note 4)

υ

a

is a dimensionless coefficient for calculating impact force.

Note 5) Average load coefficient (= ):

This coefficient is for averaging the maximum load moment at

the time of stopper impact according to service life calculations.

3. Refer to pages 1096 and 1097 for detailed selection procedures.

υ

L

1

M

E

g

: Impact speed (mm/s)

: Distance to the load’s center of gravity (m)

: Dynamic moment (N

⋅

m)

: Gravitational acceleration (9.8 m/s

2

)

: Load mass (kg)

: Load (N)

: Load equivalent to impact (at impact with stopper) (N)

: Average speed (mm/s)

: Static moment (N

⋅

m)

1.4

100

1

3

+

+

1

1090

Series

MY2

P1057-P1120-E.qxd 08.10.3 2:27 PM Page 1090

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com