NOTE

Filter 84013 and 84013A should be

mounted between delivery pump and

grease reservoir being reilled

Maximum low rate into ilter should

not exceed low rate in speciication

5

4

3

2

1*

6

7

8

9

10

11

12

13

A

B

1*

Installation

1

Shut off all grease low into grease

reservoir

2

Apply Telon-based thread sealant to all

threaded connections

3

Connect grease delivery pump outlet

hose to

1

/

2

in NPTF reill ilter inlet (

11

)

4

Connect

1

/

2

in NPTF reill ilter outlet (

12

)

to hose leading into grease reservoir

*

Indicates change

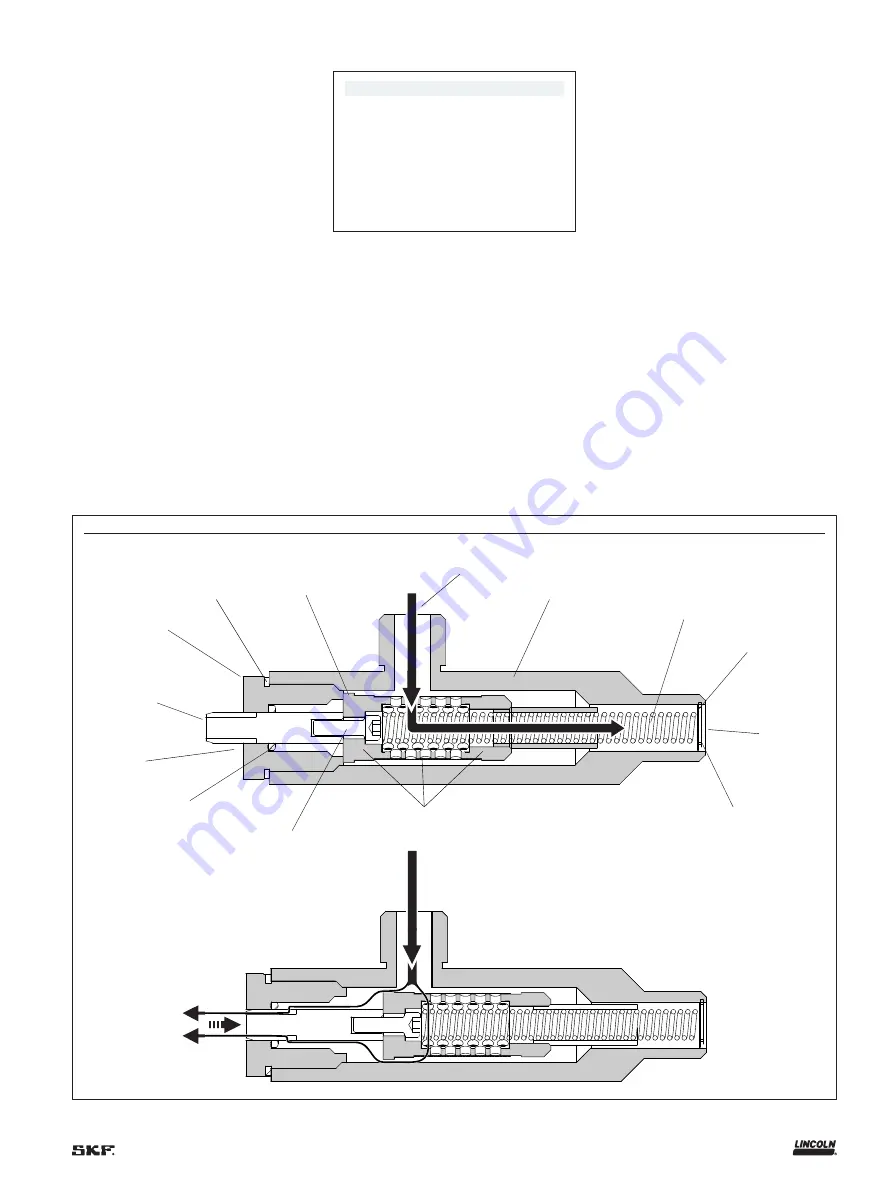

Fig. 1

Operation

Grease lows into inlet (

11

) and exits through

outlet (

12

) under normal conditions while

iltering out any impurities exceeding 250

microns in size (500 micron for 84013A)*

Under such conditions, bypass pin (

2

) is in

extended position (

Fig. 1, A

)

As contaminants are iltered out by ilter

assembly (

1

), luid pressure within ilter, or

differential pressure increases

When differential pressure from grease

ilter exceeds 200 psi

(13,8 bar)

due to

trapped contaminants, bypass pin (

2

)

retracts into ilter body (

8

) and luid bypass is

activated, releasing grease through outlet

(

13

) (

Fig. 1, B

)

.

3