3-2

INB

ON

>3-3 INC

(三)

Device signal switch

Press,

、

add or subtract, select "device signal switch" (FIG. 33), press the right button, and

enter the sub-menu interface (FIG. 34) :

3-1 signal direction of knee action switch (figure 34)

The signal direction of the knee action switch (default ON) is set,

、

and the knee action

switch signal can be turned off or turned ON through the add or subtract keys.

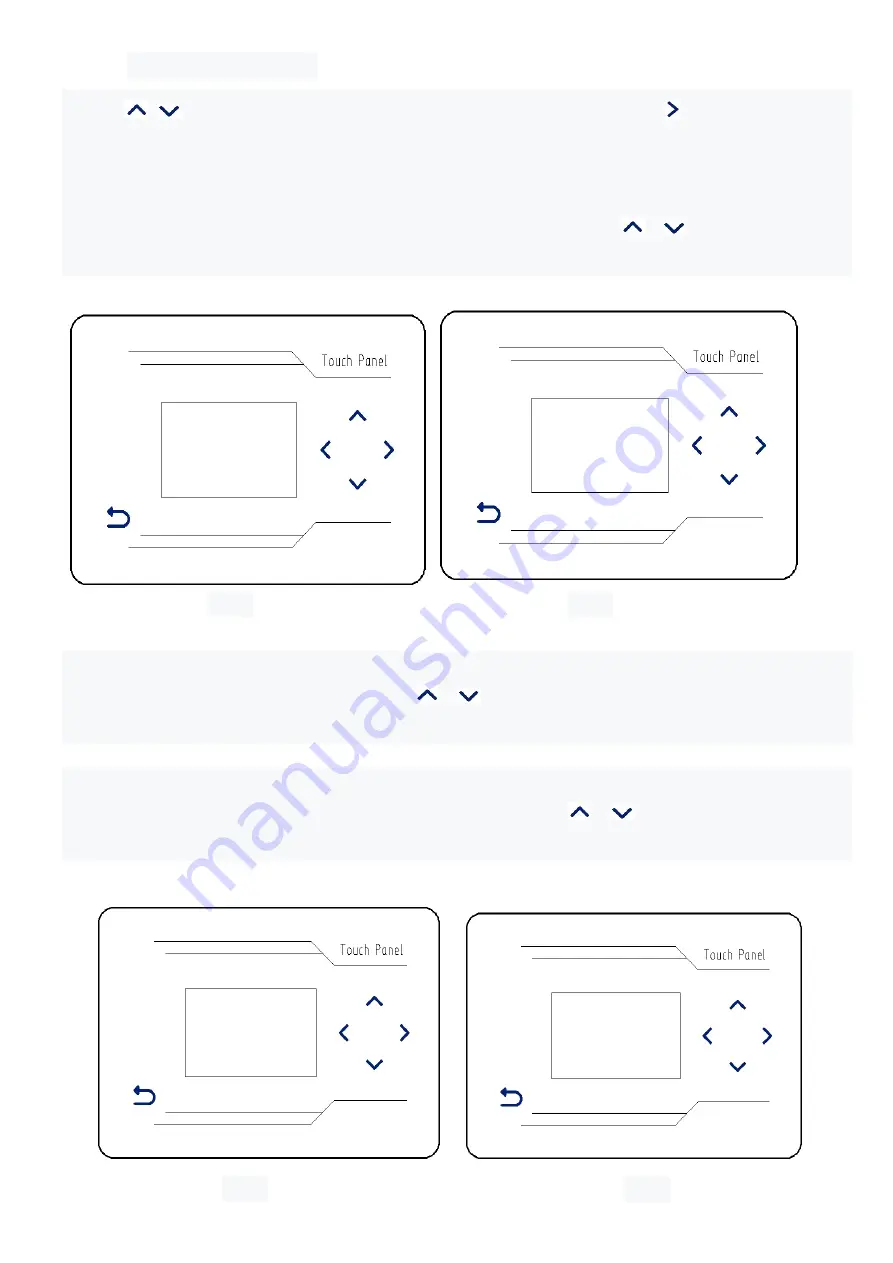

figure

35

figure

36

3-2 step approach switch (figure 35)

Step proximity switch (default ON) setting,

、

through the key, add or subtract, you can turn

off or open step proximity switch.

3-3 cloth detection of electric eye signal (figure 36)

Cloth detection electrical eye signal (default OFF) setting,

、

through the key, add and

subtract, can open or close cloth detection electrical eye signal

figure

37

figure

38

3-3

INC

OFF

>3-4 IND

3-5

OUTA

OFF

>3-6 OUTB

3-4

IND

OFF

>3-5 OUTA

Summary of Contents for ASK-ACS100

Page 1: ...ASK ACS100 ELECTRONIC CONTROL PARAMETER MANUAL...

Page 2: ...P 1 ASK ACS100 1 1 3 2 3 4 5 1 2...

Page 3: ...P 2 1 1 1 2 1 2 1 3 1 2 3 4 2 3 2 3 3 1 2 3 4 1234 4 4 5 4 3 1 1 1 2...

Page 4: ...P 3 1 3 1 4 6 1 6 4 9 1 1 1 2 1 3 1 4 1 5 1 6 1 9 1 10 1 11 1 12 1 13 6 7 1 4 1 5...

Page 6: ...P 5 1 9 1 10 1 10 1 11 1 11 1 12 12 13 1 9 12 1 9 1 10 13 1 10 14 15 1 12 001min 1 13...

Page 7: ...P 6 2 1 300 2 2 1 13 1 2 3 4 1 11 14 1 11 1 12 15 1 16 1 13 16 1 13 12 3 17 18...

Page 14: ...P 13 1 2 3 4 English A B A B 43 44 43 44 A 44 45 English 45 46 B 46 43 44...

Page 15: ...P 14 2 1 6 SR...