10

ADDING OIL

MAINTENANCE

OIL CHANGE

For the best performance and longest life, completely change the oil at least once

per year. Always dispose of hydraulic oil in accordance with local regulations.

1. Lower the saddle to its lowest position (turn the release knob anti-clockwise).

2. Remove the metal plate covering the ram.

3. Remove the oil fill bung fully from the hydraulic unit.

4. Tilt the jack and drain all of the oil into a suitable container.

Note:

Do not touch or use the handle when filling with oil.

1. Lower the saddle to its lowest position (turn the re-

lease knob anti-clockwise).

2. Remove the metal plate covering the ram.

3. Remove the oil fill bung fully from the hydraulic unit.

4. Pull back on the handle until the handle is nearly

horizontal.

5. Top the oil up if required; The oil level should be

visible in the filler hole.

6. Refit the oil fill bung.

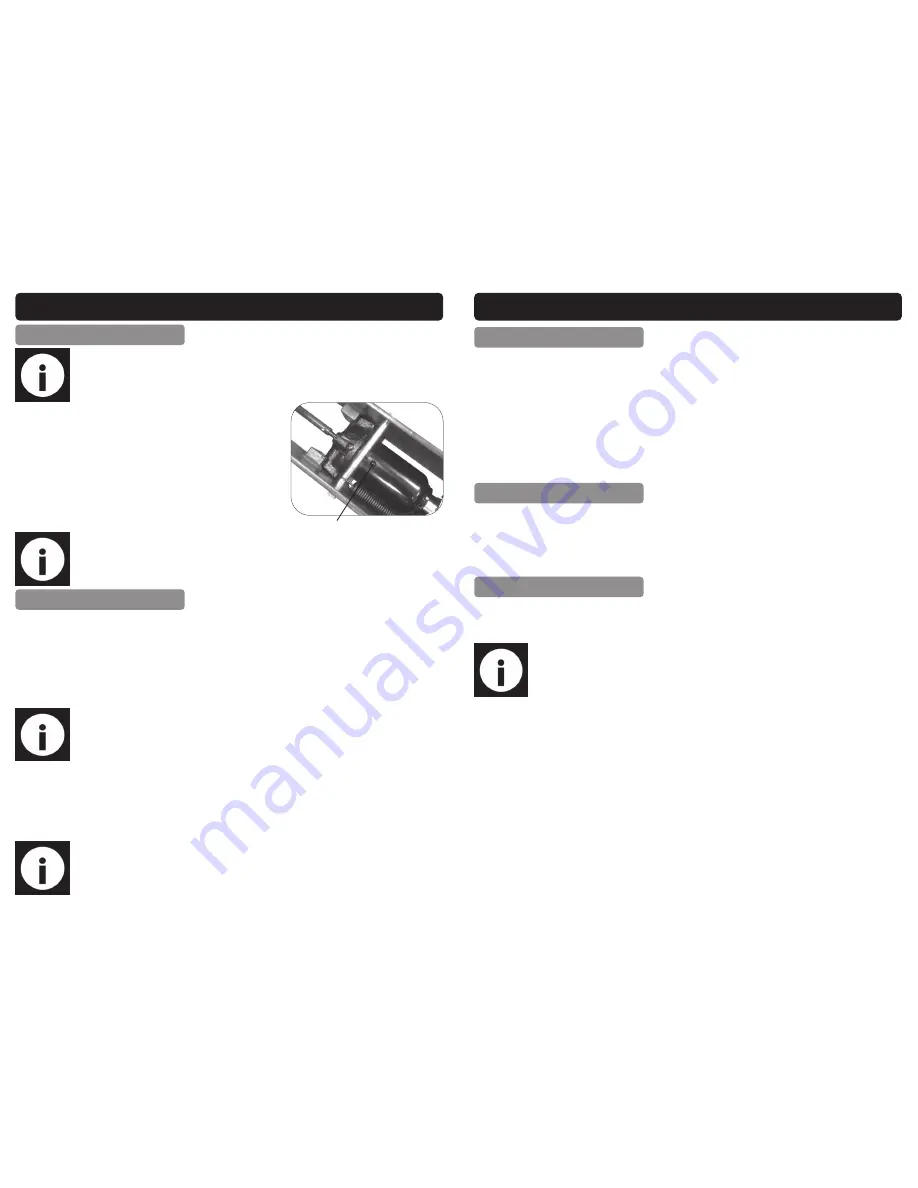

Oil fill bung

Note:

Contact your local authority on how / where to dispose of the waste

oil.

Recommended Oil -

ISO 15.

Oil Capacity - 03642

480ml (approx.)

03647

- 1050 ml (approx.).

Note:

Due to the size and weight of the jack, at least 2 persons are re-

quired to safely perform this operation.

5. Return the jack to an upright position.

6. Pull back on the handle until the handle is nearly horizontal.

7. Fill with hydraulic oil until the oil reaches the bottom of the oil fill hole.

8. Wipe away any excess oil.

9. Refit the oil fill bung & metal plate.

11

MAINTENANCE….cont

A periodic coating of light lubricating oil to pivot points, axles and hinges will help to

prevent rust and assure that wheels, castors and pump assemblies move freely.

Some grease should also be applied to the main pivot and the front wheels through

the grease nipples.

LUBRICATION

CLEANING

Periodically check the pump piston and ram for signs of rust or corrosion. Clean as

needed and wipe with an oily cloth.

1. Remove the oil fill bung.

2. Insert the handle into the handle base.

3. Turn the release knob anti-clockwise to open the release valve.

4. Pump the handle up and down quickly several times, this will purge the air from the

system.

5. Refit the oil fill bung.

Note:

Never use sandpaper or abrasive material on these surfaces.

If air gets into the hydraulic system the jack will not operate correctly and will need to

be bled. To bleed air from the hydraulic system, follow the instructions below.

BLEEDING