24

www.simplicitymfg.com | www.snapper.com

Maintenance

Regular Maintenance

SERVICING THE MOWER BLADES

Removing the Mower Blade

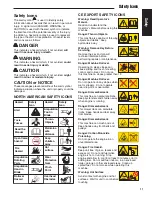

1. See Figure 17. To remove the mower blade,

wedge a wooden block between the mower blade

and the mower deck housing to keep the mower

blade from turning, then remove the mower blade

and the mower blade retaining hardware.

Inspecting the Mower Blades

1. Remove the mower blade from the unit.

See

Removing the Blade.

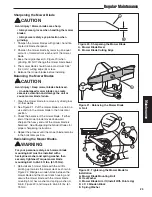

2. Inspect the mower blade (Figures 18 & 19).

Discard the mower blade if it has any of the

below conditions.

A.) Has more than .5” (12,7 mm) of the mower

blade metal removed from previous sharpening or

wear (D, Figure 18).

B.) The air lifts are excessively eroded (B & C,

Figure 19) and the notch (C) is .25” (6,35 mm)

deep or greater.

C.) Mower blade is bent or broken.

3. If the cutting edges are not sharp or have nicks,

sharpen the blades.

See Sharpening the Mower

Blades.

Figure 17. Loosening the Mower Blade for

Removal

CAUTION

Avoid injury! Mower blades are sharp.

• Always wear gloves when handling mower

blades or working near blades.

DANGER

Avoid injury! A worn or damaged blade can

break, and a piece of the mower blade could be

thrown into the operator’s or bystander’s area,

resulting in serious personal injury or death.

• Inspect the mower blade every 25 hours or at

least once a year.

• If the mower blade hits a solid object, stop the

engine immediately and inspect the mower

blade.

• Never weld or straighten bent mower blades.

Figure 18. inspecting the Mower Blade Tips

A. Mower Blade Cutting Edge

B. Square Corner

C. Air Lift

D. Wear Measurement - DISCARD Mower Blade If

greater than .5” (12,7 mm)

B

D

A

B

C

Figure 19. inspecting the Mower Blade Air Lifts

A. New Mower Blade

B. Mower Blade at Wear Limit (A notch begins to form)

C. Mower Blade in Dangerous Condition (Notch measures .25” (6,35 mm) or greater DO NOT USE.

Replace with new mower blade.)

C

A

C

A