15

3. Safety Instruction

3.1 Use it on a level paved surface.

3.2 Don’t load over the maximum capacity and ensure the balance of loading.

3.3 Don’t push and move the stacker when the load is on top.

3.3 Don’t put foot or hand under or into the lifting mechanism.

3.4 Don’t allow other person than the operator to stand in front of or near the truck when it is moving or lift-

ing/lowering.

3.5 Don’t put foot in front of the wheels, injury could result.

3.6 Don’t lift people. People could fall down and suffer severe injury.

3.7 Don’t push or pull loads.

3.8 Don’t side or end load. Load must be distributed evenly on the fork.

3.9 To cooling the temperature of power pack motor, it should be paused working for minutes after continuous

working with load. Otherwise, it might cause damage to power pack.

3.10 Recharge the battery when it has no enough power. Ensure local electric power matches the charge. Do

not discharge the battery completely.

3.11 Please close the electric control box before use.

4. Inspection before Use

Stacker is integer packing, it was adjusted. The owner should inspect the stacker before use as follows:

4.1 Ensure all parts complete and in good condition. Do not use the stacker and contact local supplier in case

of any parts missing or defective.

4.2 Visual check if there are any broken hoses or electric wires.

4.3 Check the chain and rollers for damages or corrosion.

4.4 Check the smooth movement of the wheels.

4.5 Check if all bolts and nuts are tightened firmly.

4.6 Ensure oil is full and no oil leakage in the hydraulic system.

4.7 Ensure battery has enough power. The battery has been charged before shipment.

But due to long time delivery, it would be low in power. When turn on the stacker, or when lifting loaded,

the coulometer shows 3 graduation, it needs recharged.

4.8 Connect the power, the performance of lifting and lowering fork is normal when unloaded.

4.9 Connecting power, when loaded fork lift and lower, there is no oil leak.

4.10 Place the charger at a safety place.

5. Operation Instruction

5.1 Lift/lowering the fork

5.1.1 Lock the parking brake.

5.1.2 Turn the switch to

ON

, there is power and all graduation of coulometer

is light.

5.1.3 Press the

LIFT

button, the fork will lift up. Loose the button, the fork

will stop at any position as you like. It will not slide down.

5.1.4 Press the

LOWER

button, the fork will lower down. Loose the button,

the fork will stop at any position as you like. It will not slide down.

5.1.5 To prolong the service life of electric pump, it is necessary to loose the button when the fork reach the

top position.

5.1.6 The electric pump is provided with a relief valve. When the load is over 120% of the capacity, the fork

will not lift.

Summary of Contents for EZ2515

Page 1: ...K 532 959 G 951 901...

Page 4: ...3 2 Technische Daten...

Page 9: ...8 9 Hydraulikplan...

Page 12: ...11...

Page 13: ...12 K 532 959 G 951 901...

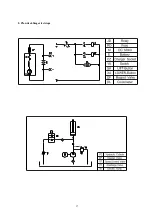

Page 19: ...18 8 Diagram of Electric Control System 9 Diagram of Hydraulic System 9 Hydraulic Diagram...

Page 21: ...20...

Page 22: ...21 K 532 959 G 951 901...

Page 28: ...27 8 Plan de c blage lectrique 9 Plan hydraulique...

Page 31: ...30...

Page 32: ...31 K532 959 G 951 901...

Page 41: ...40...