21

2.15.1 Operating cycle

Before igniting the boiler, use a voltmeter to make sure

that the electrical connection to the terminal block has

been made properly, respecting the position of line and

neutral, as shown in the diagram. Press the switch on the

control panel and check for the presence of voltage sup-

ply (warning lamp lights up). The boiler is now ready to

start working upon demand for heating or drawing off of

D.H.W.; a discharge current is sent to the ignition elec-

trode through the FM11 programmer, and the gas valve

opens at the same time. Burner ignition normally takes

place within 2 or 3 seconds.

However, it is possible for ignition failures to occur, with

consequent activation of signal indicating that the equip-

ment has “locked out”.

–

Gas failure

This may occur upon first ignition or after long periods

of boiler lay-off when there is air in the pipes. It may be

caused by the gas cock being closed or by one of the

valve coils having a break in the winding, so that the

valve cannot open.

The appliance runs through the cycle normally sen-

ding electric power to the ignition electrode. The elec-

trode continues spark discharge for a maximum of 10

sec. If the burner does not ignite, the equipment

“locks out”.

–

Ignition electrode fails to spark

This may be due to there being a break in the wire to

the electrode or to the wire not properly fastened to

the equipment electric terminal; or else, the transfor-

mer has burnt out.

In the boiler, only the gas to the burner is seen to

open. After 10 sec. the equipment “locks out”.

–

No detection of flame

This occurs when the position of phase and neutral

has not been respected on the terminal block.

There is a break in the wire to the sensing electrode or

the electrode itself is touching earth: the electrode is

worn out and needs replacing.

The continuous spark discharge of the electrode is

noted starting from ignition even though the burner is

lit. After 10 seconds have elapsed, the sparks cease,

the burner goes out, and the warning light indicating

equipment “lock-out” lights up.

When there is a sudden voltage failure, the burner shuts

out immediately; when power supply returns, the boiler

will start up again automatically.

2.16

INTERRUPTION OF THERMOCOUPLE

“MURELLE 20 CE - 20 BF CE”

The boiler is equipped with total safety devices, with

extinguishing of main burner and pilot if an accidental

overtemperature heppens in the water-gas exchanger.

Control comes about via a limit thermostat (6, Fig. 3 - 7,

Fig. 3/a) set at 85°C and a safety thermostat (11, Fig. 3 -

12, Fig. 3/a) set at 100°C, arranged in series in the circuit

of the interrupted thermocouple and overheat cut-off

device of the gas valve.

To enable re-ignition of the pilot burner (12, Fig. 3 - 5, Fig.

3/a), so restoring boiler operation, it will be necessary to

wait until the temperature in the exchanger drops below

the thermostat setting value.

2.17

SMOKE SAFETY DEVICE “MURELLE

20 R CE IONO - 20 CE - 20/25 CE IONO”

This is a safety device against possible smoke emission

into the ambience.

The safety device goes into action by blocking operation

of the gas valve when the return of smoke into the

ambience is continuous and in quantities that might con-

stitute a danger. To enable restart of the boiler, it is neces-

sary first to unscrew the cover of the thermostat and reset

the push-button (2, Fig. 18).

Before carrying out this operation, make sure that electric

power is not reaching the control panel.

Should the boiler continue to “lock out” , it will be neces-

sary to make a careful check on the flue pipe, making all

the necessary modifications and adaptations so that it

can function efficiently.

2.18

SMOKE PRESSURE SWITCH

“MURELLE 20 TX CE IONO - MURELLE BF”

Impurities and possible formations of condensate, which

are more likely in cold periods of the year, could cause

the pressure switch not to function and the boiler to fail to

start. The pressure switch is set in the factory at the opti-

mal values of 4.5 - 6 mm H

2

O for the

“20 TX - 20 BF”

ver-

sions, and 8 - 9 mm H

2

O for the

“25 BF”

version. This is

able to guarantee operation of the boiler even with air

intake and flue outlet pipes at the maximum limit of length

allowed.

In the case of replacement, the type of pressure switch

originally mounted must be used without fail. Under no

circumstances must the pressure switch for the

“20 BF”

version be installed on the

“25 BF”

version, since

otherwise the safety of operation of the appliance would

be jeopardized.

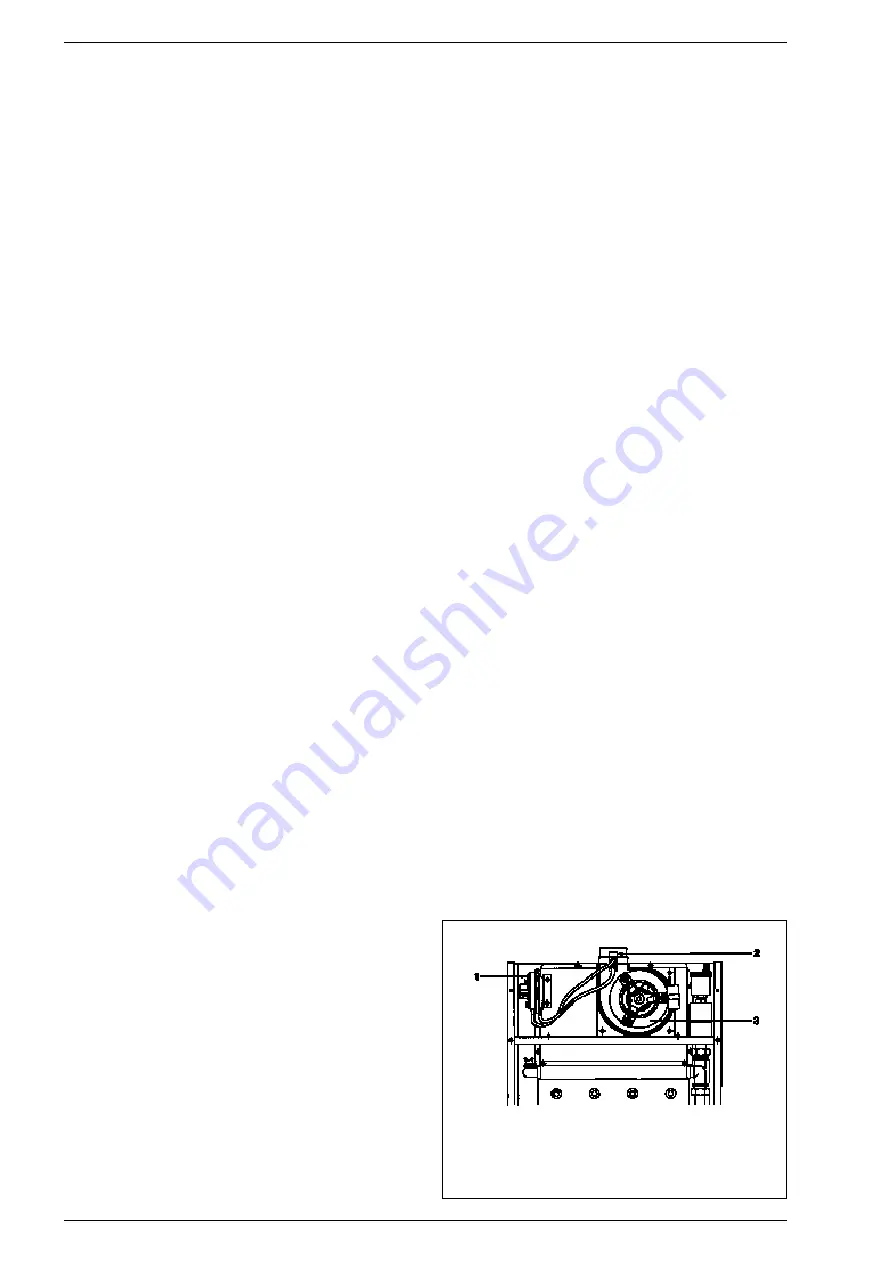

KEY

1 Smoke pressure switch

2 Venturi (

“20 TX CE IONO - 25 BF CE IONO”

versions)

3 Fan

Fig. 26