IT

ES

PT

GB

94

1.1

INTRODUCTION

“DEWY”

boilers are premix condensation

thermal appliances which use microproces-

sor technology for function control and

management. They comply with the euro-

pean

directives

90/396/CEE,

89/336/CEE, 73/23/CEE, 92/42/CEE

and with the european specifications EN

483 - EN 625.

These appliances can be fired by natural

gas (methane) and propane gas (G31).

The instructions given in this manual are

provided to ensure proper installation and

perfect operation of the appliance.

1

DESCRIPTION OF THE BOILER

1.2

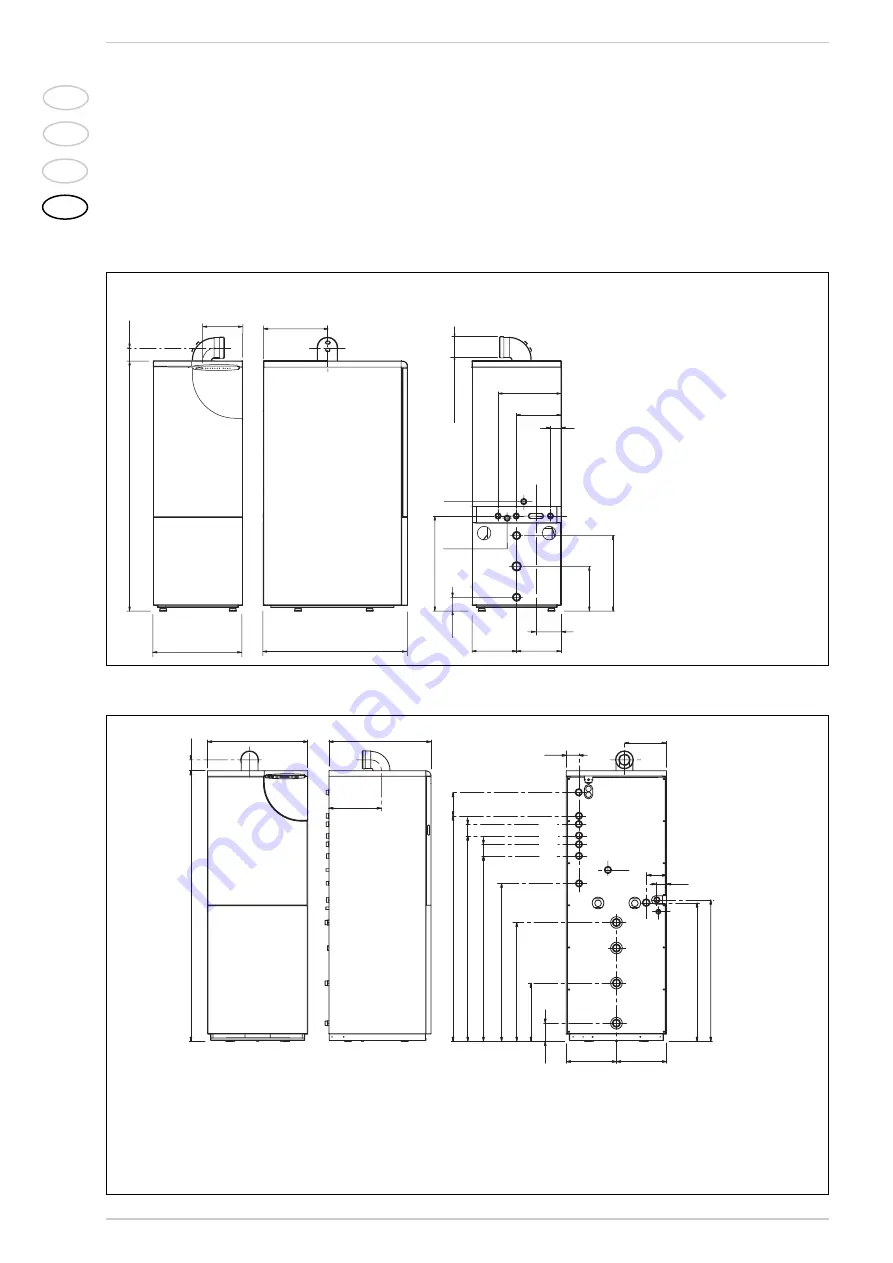

DIMENSIONS

1.2.1

“30/80” model

330

G

240

310

M

R

55

S2

C

U

S1

E

70

490

390

130

S3

230

230

745

Ø 60/1

00

230

65

1

290

460

215

Fig. 1

CONNECTIONS

R

C.H. return

3/4” (UNI-ISO 228/1)

M C.H. flow

3/4” (UNI-ISO 228/1)

G

Gas connection 3/4” (UNI-ISO 228/1)

E

D.H.W. inlet

3/4” (UNI-ISO 228/1)

U

D.H.W. outlet

3/4” (UNI-ISO 228/1)

C

Recirculation

3/4” (UNI-ISO 228/1)

S1 C.H. safety relief valve

S2 Tank unit safety relief valve

S3 Condensation outlet ø 25

600

65

1

620

610

315

252

76

M2

R2

M1

R1

M

R

S1

C1

S3

G

S2

117

62

U

C

E

10

9

34

9

71

2

94

6

70

11

0

9

1

229

70

1

3

49

1

4

0

300

300

828

84

6

1.2.2

“30/130” model

CONNECTIONS

R

Zone 1 system return

3/4” (UNI-ISO 228/1)

R1

Zone 2 system return (optional)

3/4” (UNI-ISO 228/1)

R2

Zone 3 system return / Low

temperature return (optional)

3/4” (UNI-ISO 228/1)

M2

Zone 3 system delivery / Low

temperature delivery (optional)

3/4” (UNI-ISO 228/1)

M1

Zone 2 system delivery (optional)

3/4” (UNI-ISO 228/1)

M

Zone 1 system delivery

3/4” (UNI-ISO 228/1)

G

Gas connection

3/4” (UNI-ISO 228/1)

E

D.H.W. inlet

3/4” (UNI-ISO 228/1)

U

D.H.W. outlet

3/4” (UNI-ISO 228/1)

C

Recirculation

3/4” (UNI-ISO 228/1)

C1

Recirculation pump kit (optional)

1/2” (UNI-ISO 228/1)

S1/S2 C.H. safety relief valve/tank

S3

Condensation outlet ø 25

Fig. 1/a

Summary of Contents for DEWY 30/130

Page 33: ......