20

is set-up for NATURAL GAS; with the con-

nector

linked-on

, the boiler is ready for

LPG.

–

“ANN. RIT.” connector

(5 fig. 17)

In the heating phase, the electronic board

is programmed to include a burner tech-

nical delay interval of approx. 90 seconds,

which occurs both at system cold star-

ting and at subsequent re-ignitions. The

aim is to overcome the problem of repea-

ted ignitions and turning off with very

short time intervals between. This could

occur in particular in systems presenting

high head losses.

At each restart after the period of slow

ignition, the boiler will set itself for about

1 minute at the minimum modulation

pressure, and will then move to the hea-

ting pressure value set.

When the connecting link is inserted,

both the programmed technical pause

and the period of operation at minimum

pressure in the startup phase will be can-

celled. In this case, the times elapsing

between turning off and subsequent re-

ignition will depend on a temperature dif-

ference of 5°C detected by the SM sen-

sor (heating flow sensor).

–

DIP SWITCH

(13 fig. 17)

Check that the switches are positioned

as shown.

Flashing red led,

communication fault

with “Logica Remote Control”

Green led off if

power is cut-off

Flashing red led, water

pressure is too low (*)

Flashing red led, heating sensor fault (SM)

Flashing red led,

plant safety

valve tripped (*)

Red led on, ignition blocked:

rotate selector CR/OFF/SUM/WIN/RESET

to release position (

)

to restore operation

Flashing red led, safety/smoke stat tripped.

Rotate selector CR/OFF/SUM/WIN/RESET

to release position (

)

to restore operation

Flashing red led, fan fault.

30 minutes after the fan has switched off,

the board will attempt a restart

(*) When all 0.5 to 2.5 bar leds are off, check the water

pressure transducer connection.

WARNING: the operation of plants with open vessels is

guaranteed only for static pressures above 0.7 bar.

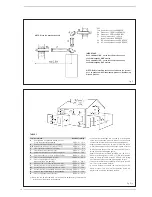

Fig. 16

Flashing red led, flame detection circuit fault

15

13

1

3

5

7

8

9

10

11

12

14

6

6

10

KEY

1 Ignition electrode earth faston

3 Fuse (1,6 AT)

5 “ANN. RIT.” connector

6 “POT. ACC.” trimmer

7 Conector “MET-GPL”

8 D.H.W. potentiometer

9 Ionisation electrode faston

10 “POT. RISC.” trimmer

11 C.H. potentiometer

12 Selector CR/OFF/SUM/WIN/RESET

13 DIP SWITCH

14 Connector “Modureg Sel.”

15 Connector “Albatros”

NOTE: To gain access to trimmers (6) and (10), unscrew the central hea-

ting potentiometer knob

Fig. 17

Flashing red led, flowmeter fault