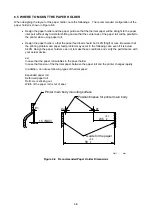

The divided printing method is described below (See Figure 5-1):

(1) Pause

state

Inactivate the motor and always make DST signal of the thermal head "Low".

(2) Start

step

Excite the motor by the same phase which is output just before the motor stops.

(3) 1st dot line

Activate the thermal head once every 2 steps of the motor drive signal. Configure 1 dot line by

4 steps of the motor drive signal.

At the 1st step of the motor drive signal, start activation of the thermal head by synchronized the DST

signal and printing the 1st half dot line at the 1st dot line by DST.

After 1st step of the motor drive signal is completed, input the 2nd step of the motor drive signal. (It is not

necessary to synchronize the activation of the thermal head.)

After printing the 1st half dot line at the 1st dot line, the 3rd step of the motor drive signal, start activation

of the thermal head by synchronized the DST signal and printing the 2nd half dot line at the 1st dot line

by DST..

After 3rd step of the motor drive signal is completed, input the 4th step of the motor drive signal. (It is not

necessary to synchronize the activation of the thermal head.)

Input the DST signal after transferring the data which is printed into the "SHIFT REGISTER" in the

thermal head. And latch to "LATCH REGISTER" of the thermal head by inputting the DST signal.

(4) Procedures that follows the 2nd dot line

Drive the motor in the same way as the way for the 1st dot line. Repeat the motor driving and thermal

head activation.

5-2