the fuselage and aligned with the centerline of the fuselage.

Wipe off any excess glue with alcohol. Adjust as needed

and tape securely. Remove the wing and allow the glue to

cure completely.

❑

16) Install a right and left rudder horn to the bottom of the

rudder using #4 x 3/8" sheet metal screws. The rudder has

inset plywood mounting pads on each side for this purpose.

The two rudder horns directly oppose one another and

should be lined up with the pull-pull exits at the bottom rear

of the fuselage. The rudder is now hinged to the fin using

epoxy glue on the hinges - remember to protect the hinge

knuckles with petroleum jelly. Clean off any excess glue

and allow to cure.

❑

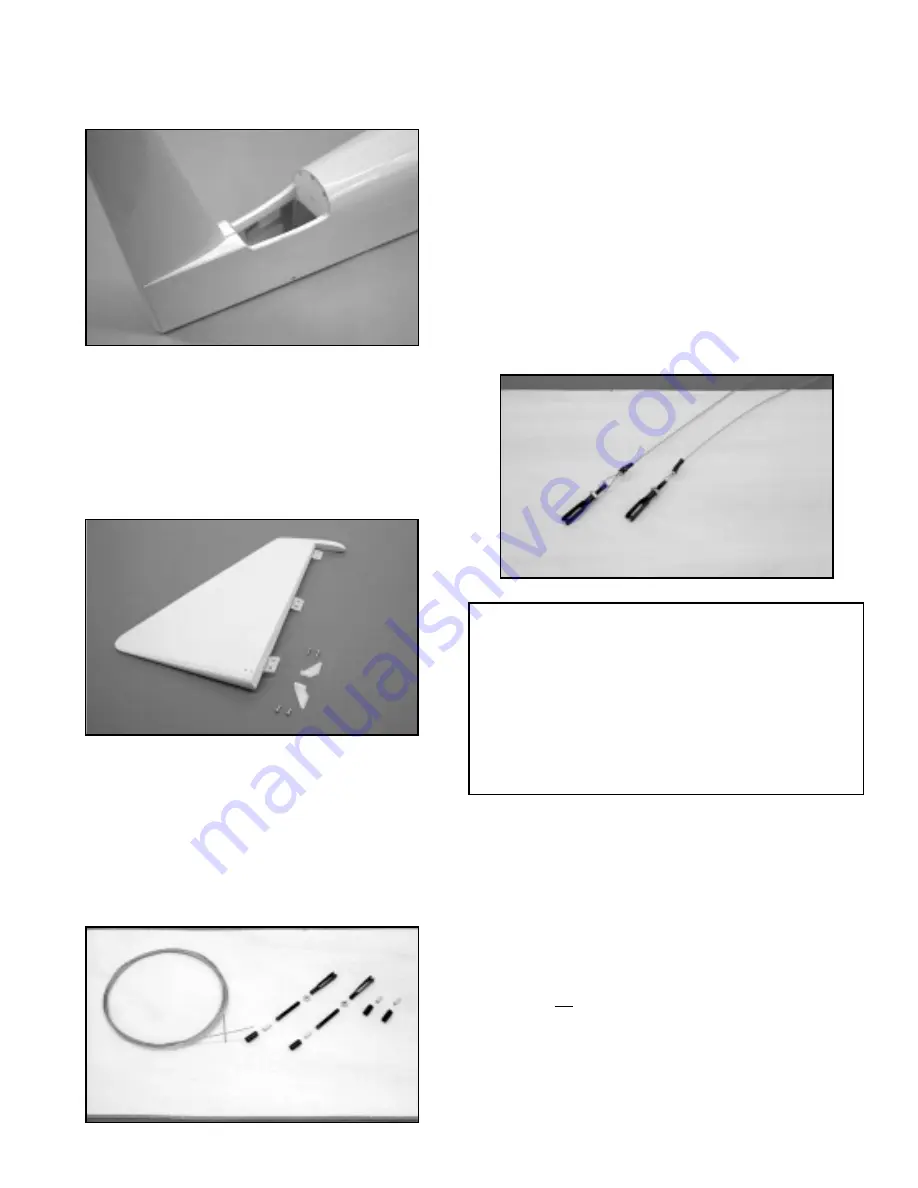

17) The rudder pull-pull system is now installed. Begin by using

your radio system to accurately center the rudder servo.

Install the output arm onto the rudder servo. From your kit

contents, locate the package containing the coil of .021

braided steel cable, rigging couplers, heat shrink tubing

and aluminum crimps.

You will also need two 4-40

threaded R/C links and two 4-40 hex nuts. Cut the braided

cable into two equal 36" lengths (a carbide cut-off wheel

works great) and cut the heat shrink tubing into four

1/2" lengths.

Place one 1/2" length of heat shrink tubing onto one end of

the cable, followed by one of the 1/2" aluminum tubes.

Thread the end of the cable through the small hole in the

end of the threaded rigging coupler, giving yourself about

4" - 5" to work with. Make a half loop around the rigging

coupler hole and run the short end of the cable through the

aluminum tube.

Pull the tube up to the rigging coupler,

about 1/2" away from it. Take the short end of the cable and

loop it back around and through the aluminum tubing,

pulling it tight. Use a pliers or a crimping tool to squeeze the

aluminum tube tightly over the cable in two places, locking

it in place. Cut off the excess short end of the cable. Press

the heat shrink tubing in place over the aluminum tube and

use heat to shrink it in place.

Thread a 4-40 hex nut

completely onto the rigging coupler, followed by a 4-40 R/C

link. Center the link approximately onto the rigging coupler

threads. Repeat this process on the remaining length of

cable.

These two prepared ends will be located at the

rudder.

Feed the bare end of the cables into the pull-pull exits at the

bottom rear of the fuselage and up to the rudder servo

location. Use masking tape to hold the rudder in neutral

with the fin. Connect the R/C links to the rudder horns using

the same hole locations on each horn. Turn the fuselage

upside down on your bench and make the cable

connections to your servo output arm. Start by placing a

1/2" length of heat shrink tubing onto the cable, followed by

a 1/2" aluminum tube. Thread the bare cable end through

a hole in your output arm with a half loop back into and

through the aluminum tubing. Pull the cable to remove any

slack - not tight - and slide the aluminum tube up to the

output arm, about 1/2" away. Re-loop the bare cable end

through the aluminum tubing and pull it tight. Crimp the

tubing in two places and cut off the excess cable. Press the

heat shrink tubing in place over the aluminum tube and use

heat to shrink it tight.

Repeat this process with the

remaining cable on the opposite side of the output arm.

With the rudder still taped in neutral, adjust the R/C links at

15

PULL-PULL GEOMETRY:

In order to make this or any

pull-pull system work correctly, without binding or placing

undue stress on the servo, the connections must have the

proper geometry. This is simply a matter of making the

spacing of the two required connections at the rudder horns

and those at the servo output arm, the same distance apart.

Using the after-market DuBro Super Strength output arms, we

used the two outer holes, which have a spacing of 2".

Therefore, at the rudder horns, we made our connections at

the center holes on each horn, providing 2" of spacing. Doing

this assures smooth, non-binding rudder action.

Summary of Contents for CAP 231EX

Page 26: ......