2

These instructions are to be used in conjunction

w ith the fire codes and ordinances for your specific

area which can be obtained from your local

building inspector for Fire M arshall. If required, the

proper perm it m ust be obtained! To protect your

fam ily and property, you should determ ine the

applicable codes and ordinances and strictly

adhere to them .

INSTALLATION INSTRUCTIONS

• Installing a w ood or coral heater is different than

other fuel burning appliances.

• Failure to install correctly could result in a serious

fire w ith loss of life and property.

A proper draft is absolutely essential to achieve

satisfactory perform ance.

• Too little draft w ill cause poor burning and

sm oking.

• Too high a draft w ill cause the unit to burn too hot

and use excessive fuel.

• The draft reading should be from .04 to .07 inches

of w ater colum n (.06 W .C. is the desired draft). It

is the responsibility of the user to obtain the

proper draft range.

• Low draft conditions may be corrected by using a

larger flue pipe, shorter connector pipe, or

extending the chim ney height.

• High draft conditions may be corrected by

installing a barom etric dam per.

• A qualified servicem an should be consulted of

correction of chim ney draft.

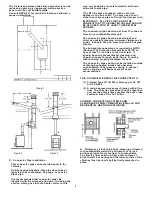

A.

CHOOSING A LOCATION

A central location is most desirable, how ever, the

m inim um required run of pipe to the chim ney

should be the deciding factor.

Shenandoah Heaters must use an approved

system for venting flue gases.

Figures

2 - 5 indicate various methods.

B. PRIOR TO INSTALLATION

1.

Rem ove carton, crating and all packing

m aterial from the heater.

2.

Fire the stove outdoors to cure the paint, and

burn off odor of oils and solvents used in

m anufacturing. Could cause unpleasant odors

in the hom e.

C. CLEARANCE FOR SHEANDOAH HEATERS

(Floor

Protector)

1.

SET THE HEATER ON A NON-COM BUSTIBLE

FLOOR PROTECTOR W ITH AN R-VALVE OF

1.0 OR LISTED FLOOR PROTECTION that

covers an area 8” larger than the heater on

three sides and extends 16” beyond the ash

and loading doors and under the chim ney

connector 2” beyond each side.

2.

IF APPROVED FLOOR PROTECTION IS NOT

USED: Use the follow ing calculation to

determ ine if a proposed alternate floor

protector meets the requirem ents listed in the

appliance manual.

a.

Convert specification to R-value.

i. R-value is given – no conversion is needed.

ii. K-factor is given w ith a required thickness

(T) in inches: R = 1/k x T

iii. C-factor is given: r = 1

b. Determ ine the R-value of the proposed

alternate floor protector.

i.

Use the formula in step (a) to convert

values not expressed as ”R”.

ii. For multiple layers, add R-values of each

layer to determ ine the overall R value.

c. If the overall R-value of the system is greater

than the R-value of the specified floor

protector, the alternate is acceptable..

Exam ple:

The specified floor protector should be ¾ inch

thick material w ith a K-factor of 0.84.

The

proposed alternate is 4” brick w ith a C-factor of

1.25 over 1/8” mineral board with a K-factor of

0.29.

Step (a.) Use the form ula above to convert

specification to R-value.

R = 1/k x

T = 1/0.84 x .75 = 0.893

Step (b.) Calculate R of proposed system

4” brick of C= 1.25, therefore

R brick = 1/C = 1/1.25 = 0.80

1/8”m ineral board of k=0.29, therefore

R min.bd = 1/0.29 x0.125 = 0.431

Total R = Rm ineral board =

0.8 + 0.431 = 1.231

Step (c.) Com pare proposed system R of 1.231 to

specified R of 0.893. Since proposed

system R is greater than required, the

system is acceptable.

Definitions:

Therm al Conductance = C = Btu = W

(hr)(ft )( F)

(m )( K)

2

B

2

B

Therm al Conductance =

k = Btu = W = Btu

(hr)(ft )( F)

(m )( K)

(hr)(ft)( F)

2

B

2

B

B

Therm al Conductance = R = (ft )(hr)( F) = (m )( K)

2

B

2

B

Btu

W

3.

Do not install in closets or alcoves.

4.

Keep combustibles at least three feet from the

heater. This includes furniture, magazine racks,

rugs, clothing and firew ood.

Do not dry clothes on or w ithin three feet of the

heater, or store flam m able liquids in the sam e room

as the heater.

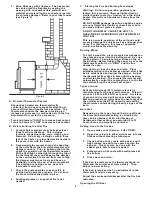

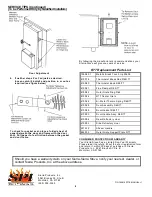

M inimum clearances from com bustible materials

w ithout protection:

M odel R77 ( See figure 1)

Sides Back Fuel Door Top Connector Pipe

A B

36" 36" 36" 36" 18"

5.

M inimum clearances from com bustible materials

w ith protection: