en

Positioning and connecting

18

Connection

■

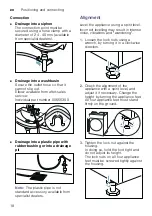

Drainage into a siphon

The connection point must be

secured using a hose clamp with a

diameter of 24 - 40 mm (available

from specialist dealers).

■

Drainage into a washbasin

Secure the outlet hose so that it

cannot slip out.

Elbow available from after-sales

service:

Individual part number 00655300

■

Drainage into a plastic pipe with

rubber bushing or into a drainage

pit

Note:

The plastic pipe is not

standard accessory, available from

specialist dealers.

Alignment

Level the appliance using a spirit level.

Incorrect levelling may result in intense

noise, vibrations and "wandering".

1.

Loosen the lock nuts using a

wrench, by turning it in a clockwise

direction.

2.

Check the alignment of the

appliance with a spirit level, and

adjust it if necessary. Change the

height by turning the appliance feet.

All four appliance feet must stand

firmly on the ground.

3.

Tighten the lock nut against the

housing.

In doing so, hold the foot tight and

do not adjust its height.

The lock nuts on all four appliance

feet must be screwed tightly against

the housing.