Functions

7.1 Overview of the inverter functions

Inverter with CU240B-2 and CU240E-2 Control Units

156

Operating Instructions, 07/2010, FW 4.3.2, A5E02299792B AA

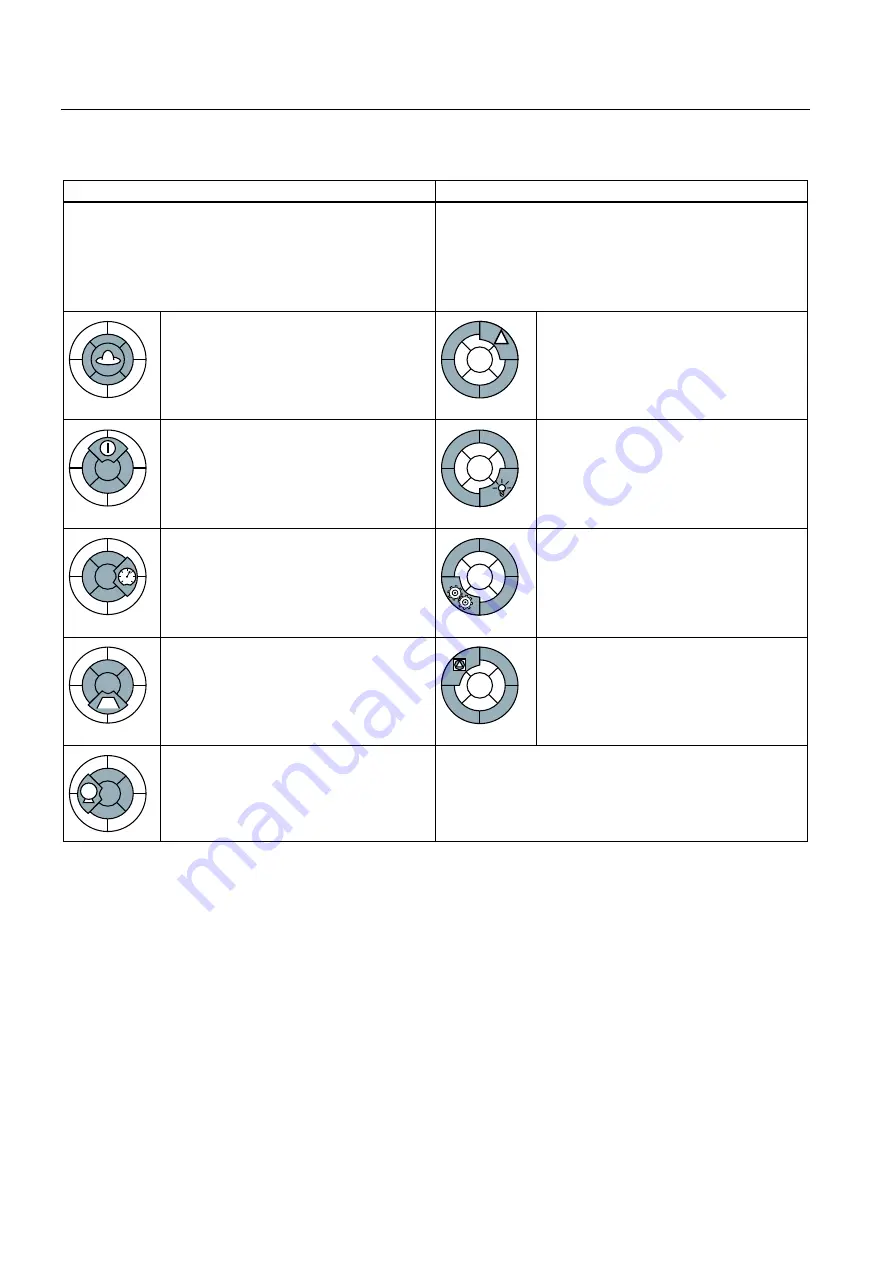

Functions relevant to all applications

Functions required in special applications only

The functions that you require in your application are

provided in the center of the function overview above.

In the quick commissioning, the parameters of these

functions are assigned an appropriate basic setting, so that

in many cases the motor can be operated without having to

assign any other parameters.

The functions whose parameters you only need to adapt

when actually required are located at the outer edge of the

upper function overview.

Inverter control is responsible for all of the

other inverter functions. Among other

things, it defines how the inverter responds

to external control signals.

Inverter control (Page 157)

The production functions avoid overloads

and operating states that could cause

damage to the motor, inverter and driven

load. The motor temperature monitoring,

for example, is set here.

Protection functions (Page 175)

The command source defines where the

control signals are received from to switch

on the motor, e.g. via digital inputs or a

fieldbus.

Command sources (Page 158)

The status messages provide digital and

analog signals at the outputs of the Control

Unit or via the fieldbus. Examples include

the actual speed of the motor or fault

message issued by the inverter.

Status messages (Page 186)

The setpoint source defines how the speed

setpoint for the motor is specified, e.g. via

an analog input or a fieldbus.

Setpoint sources (Page 159)

The technological functions allow you to

activate a motor holding brake or

implement a higher-level pressure or

temperature control using the technology

controller, for example.

Technological functions (Page 187)

The setpoint processing uses a ramp-

function generator to prevent speed steps

occurring and to limit the speed to a

permissible maximum value.

Setpoint calculation (Page 166)

The safety functions are used in

applications that must fulfill special

requirements placed on the functional

safety.

Safe Torque Off (STO) safety function

0

The motor closed-loop control ensures that

the motor speed or torque follows its

setpoint.

Motor control (Page 168)