Operating Instructions (compact)

1.6 Connecting

SIMATIC Panel PC 577

Operating Instructions, Release 04/2006, A5E00795255

1-15

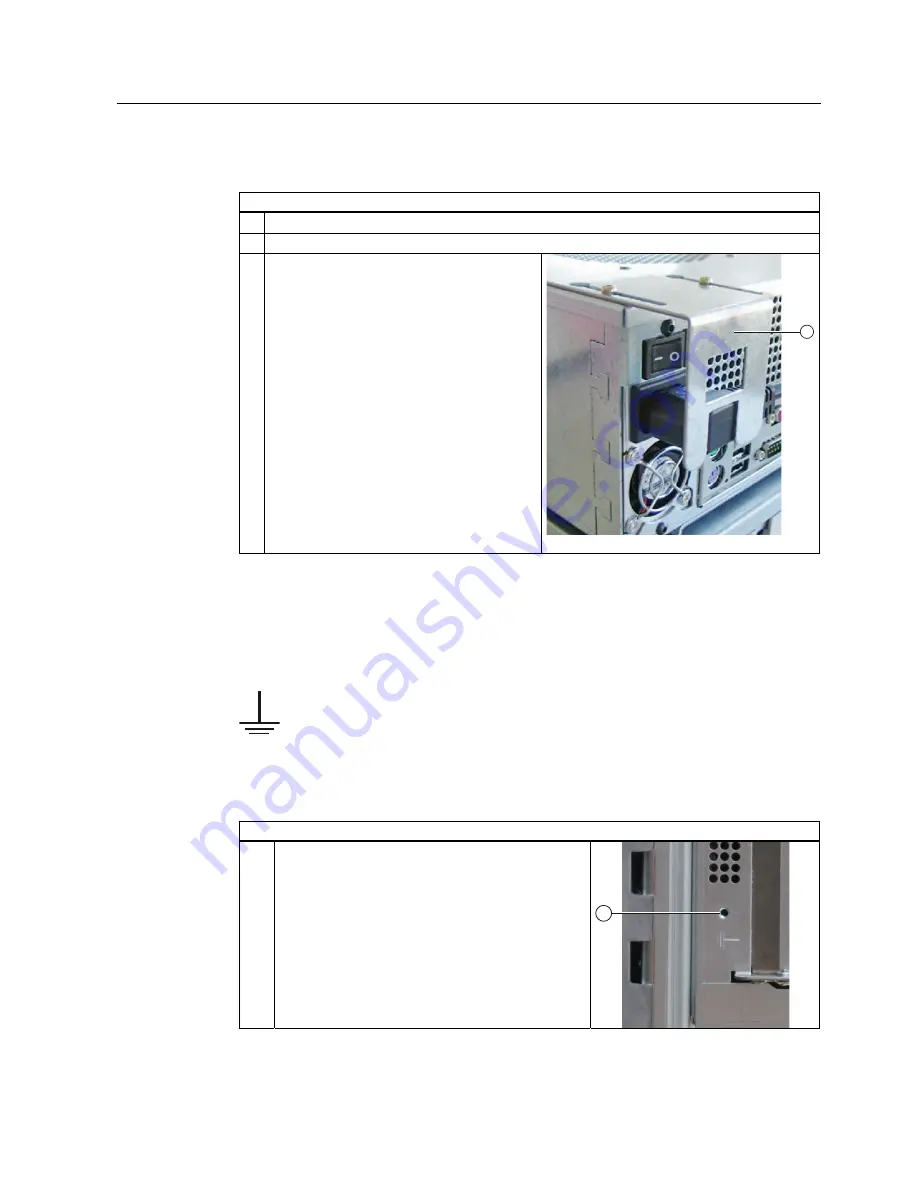

Connecting the power supply

Steps for connecting the device to the 110 / 230 V AC power supply

1 Switch off the AC power source.

2 Connect the power supply using the plug.

3 Lock the power plug to the device (1).

1.6.3

Connecting the equipotential bonding

A low-impedance ground connection ensures that interference signals generated by external

power supply cables, signal cables or cables to the I/O modules are safely discharged to

ground. The equipotential bonding connection of the device is located at the connection

elements of the computer unit and is identified by the following symbol:

Figure 1-4

Equipotential bonding

Connecting the equipotential bonding

Required tool for equipotential bonding terminal: TORX T20 screwdriver

Steps for connecting the equipotential bonding

(1) Connect the equipotential bonding connection (M4

thread) (1) on the device (large surface, large-area

contact) with the central grounding point of the control

cabinet.

The minimum conductor cross-section may not

amount to less than 5 mm

2

.