PRESSURE CONTROL

(B and C series only)

A capped potentiometer is located on the face

plate of the diaphragm pump. This potentiometer

is for pressure control or power to the pump

solenoid. Since the PolyBlend unit is equipped

with a 20 PSI backpressure/check valve, the

potentiometer should be set for full power or full

clockwise.

NOTE:

This is preset at the factory. In a case

where obvious over-pumping is present, this

potentiometer may be adjusted counter-

clockwise.

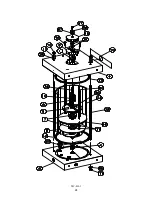

Liquifram (Diaphragm) Replacement

When replacing the Liquifram, valve balls, seal

rings and the injection check valve spring should

also be replaced.

1. Carefully depressurize, drain and

disconnect the pump discharge and suction lines.

Place the suction tubing into a container of

mineral oil. Turn the pump on to flush the head

assembly. Once the pump head has been flushed,

lift the suction tubing out of the mineral oil and

continue to pump air into the pump head until the

pump head is purged.

2. Start the pump. While running, set the

stroke knob to zero and turn the pump off.

NOTE:

See section on proper zeroing.

3. With the unit off, unscrew the Liquifram

by carefully grasping the outer edge of the

Liquifram and turning it counter clockwise.

Discard old Liquifram disk if so equipped (locate

behind the Liquifram) and check that the size

code matches the size code on the replacement

Liquifram (see illustration).

4. Reinstall the disk so alignment pin on the

disk (if present) seats in the recessed hole in the

EPU.

WARNING:

Take care not to scratch the Teflon

face of the new Liquifram.

5. Start the pump and turn the stroke knob to

the setting indicated on the Stroke Setting Chart

which matches the pump model number located

on the pump dataplate. With the pump stoking

(running), screw on the new Liquifram clockwise

until the center begins to buckle inward. Stop the

pump.

Liquifram Stroke Setting Chart

Pump Series

Stroke Knob Settings

A11 AA, B72, C72, 90%

C77

70%

6. Grasp the outer edge of the Liquifram

and adjust by screwing it in or out so that the

center of the Liquifram is flush with the outside

of the spacer edge (see illustration).

7. Once the Liquifram is properly

positioned, remount the pump head to the spacer

using the four (4) screws. Tighten in a crisscross

pattern. After one week of operation, recheck the

screws and tighten if necessary.

12

Summary of Contents for PolyBlend PB200-2

Page 17: ...15 ...

Page 18: ...16 ...

Page 19: ...17 ...

Page 20: ...18 ...

Page 21: ...19 ...

Page 22: ...20 ...

Page 24: ...200 D 007 ...

Page 26: ...MC 0101 24 ...

Page 28: ...Blank Page 26 ...

Page 30: ...OPD 0001 Post Dilution Static Mixer Assembly P N 5860001 28 ...

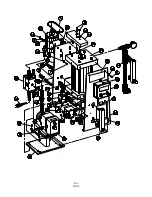

Page 32: ...Series AA7 Drive Assembly Exploded View Diagram 30 ...

Page 35: ...33 ...

Page 36: ...34 ...