Technical Instructions

OpenAir™ GCA Series Spring Return 160 lb-in Electronic Damper Actuator

Document No. 155-173P25

May 19, 2014

Page 8

Siemens Industry, Inc.

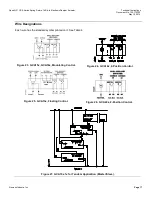

Figure 11. Heater/Weather

Shield Assembly.

985-106:

Provides protection for GIB, GBB

and GCA OpenAir actuators down to

temperatures of -58°F

(-50°C). Assembly includes:

•

Weather Shield

•

Heater Kit

Figure 12.

499 Ohm Resistor Assembly Kit.

985-124

: Used for converting a 4 to 20 mA

controller output signal into a 2 to 10 Vdc

actuator signal.

Service Parts

985-003

Position Indicators

(10/pkg.)

985-004

Standard Shaft Adapter.

985-006

Anti-rotation (Mounting)

Bracket.

985-008

Conduit Adapter,

1/2-inch (12 mm)

for 1/2-inch NPT

Connector.

Figure 13. Orderable Service Parts.

Operation

GCA12x and GCA22x: 2-Position Control

When power is applied, the actuator coupling moves toward the open position 90°.

GCA13x: Floating Control

A floating control signal controls the damper actuator. The actuator's angle of

rotation is proportional to the length of time the signal is applied. A 24 Vac/dc control

signal to Y1 causes the actuator coupling to rotate clockwise. A 24 Vac/dc control

signal to Y2 causes the actuator coupling to rotate counterclockwise.

With no control voltage, the damper actuator holds its position.

GCA16x and GCA15x: Modulating Control

A continuous 0 to 10 Vdc or 2 to 10 Vdc signal from a controller to wire Y operates

the damper actuator. The angle of rotation is proportional (or inverse proportional) to

the control signal. A 0 to 10 Vdc, or 2 to 10 Vdc position feedback output signal is

available between wires U and G0 (system neutral) to monitor the position of the

damper actuator.