21/44

Siemens

GMA..1 actuators with spring return

CM2Z4614en

Building Technologies

2018-01-11

6 Wiring

notes

Prior to wiring, study all information in the following sections:

∂

"Safety notes" in chapter 4.1,

∂

"Device-specific regulations" in chapter 4.2,

∂

"Notes on EMC optimization" in chapter 4.3,

∂

"Diagrams" in chapter 9, and the

∂

HVAC plant diagram.

∂

This chapter is written for AC/DC24 V and AC 230 V (Information for AC 24... 48 V

on inquiry)

6.1 Permissible line length and cross-sectional

areas

The line lengths and cross-sectional areas depend on the actuators power consumption

and the permissible voltage drop of the connection lines to the actuators. Determine the

necessary line length from the following diagram and the formulas.

To determine the line length and cross section, adhere to the permissible operating

voltage tolerance at the actuator (see chapter 8, "Technical data") in addition to the

permissible voltage drop between the signal and supply lines (see table below).

The line sizing between the controller and the actuators depends on the actuator type

used and is determined on the following basis.

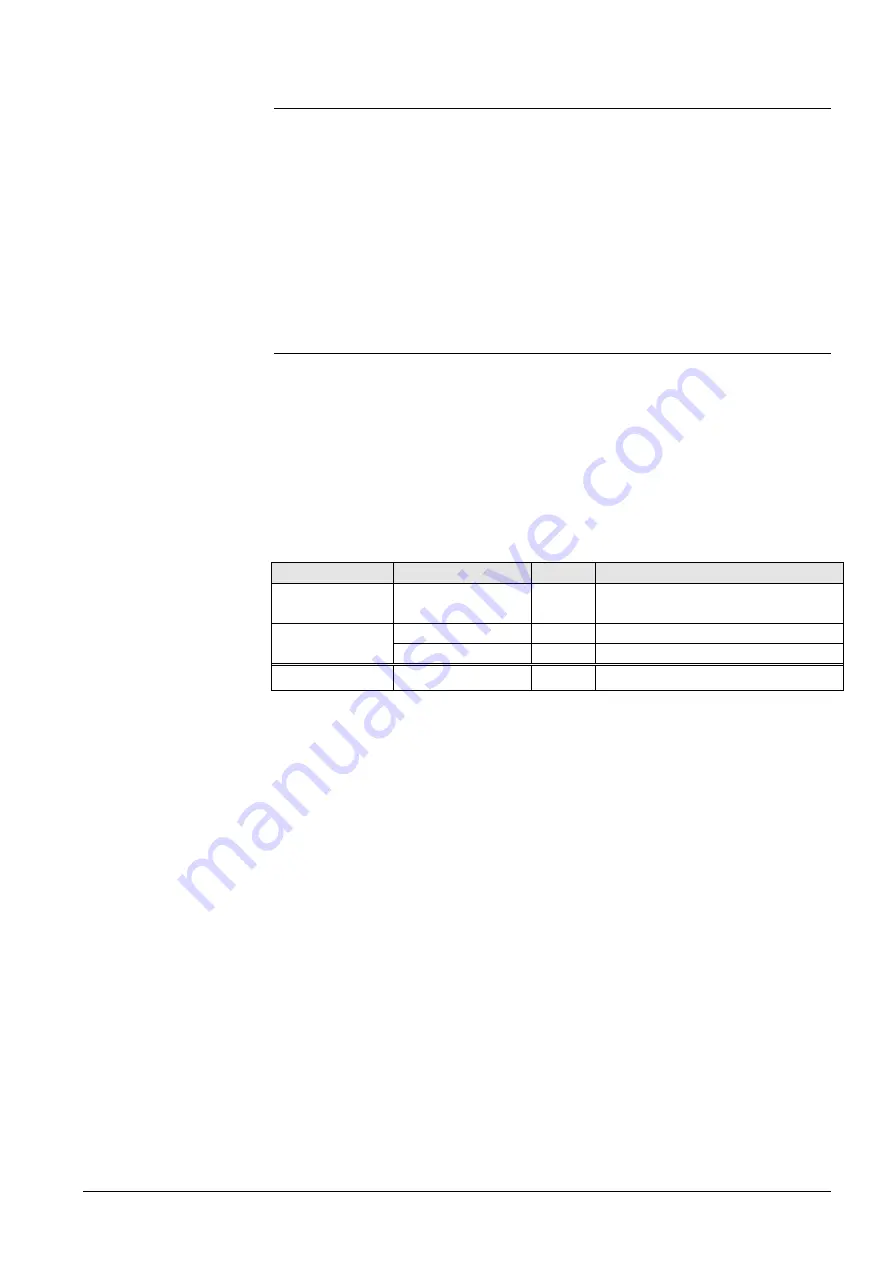

Type

Operating voltage

Line

Max. permissible voltage drop

GMA12..1

GMA13..1

AC/DC 24 V

G0, G

Y1, Y2

4 % each (tot. 8 %) of AC/DC 24 V

GMA16..1..

AC 24 V

G0, G

4 % each (tot. 8 %) of AC 24 V

DC 24 V

G0, G

1 % of DC 10 V

GMA32..1

AC 230 V

L, N

2 % each (tot. 4 %) of AC 230 V

Consider the following criteria:

∂

For modulating control and DC 24 V operating voltage:

The permissible positioning signal error caused by a voltage drop in the line current

(direct voltage mean value) on the G0 line must not exceed 1%.

∂

The G0 line's voltage drop caused by surges in the DC circuit in the actuator may not

exceed 2 Vpp.

∂

In the case of improper sizing of the G0 line, actuator load changes may cause

natural oscillation due to a change in the DC voltage drop.

∂

The supply voltage loss at AC 24 V may not exceed 8% (4% over G0 line).

Introduction

Note

Note

Permissible voltage drop

Notes on the G0 line

(GMA16..1)