Page 8

Milltronics ILE-37 – INSTRUCTION MANUAL

7ML19985CW01

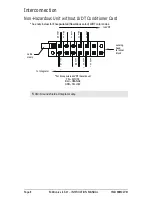

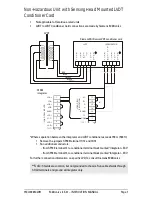

Non-Hazardous Unit with Remote-Located LVDT

Conditioner Card

*Where separation between the Integrator and LVDT conditioner exceeds 150 m (500 ft):

•

Remove the jumpers SF500 terminal 11/12 and 13/14

•

Run additional conductors:

- from SF500 terminal 12 to conditioner terminal block marked "InteEXC"

- from SF500 terminal 13 to conditioner terminal block marked "Integrator –EXC"

For further connection information on specific LVDTs, consult Siemens Milltronics.

♦

Note:

Shields are common, but not grounded to chassis. Run cable shields through

SHLD terminals and ground at Integrator only.

11

14 1

2

11

1

6

12

2

7

13

3

8

14

15

16

17

4

9

5

10

18

V+

S+

S-

V-

SHLD

-L

O

A

D

C

E

LL-

EXC

IT

A

T

IO

N

LCA+

LCA-

LCB+

LCB-

SHLD

LCC+

SIG

LCC-

COM

LCD+

CNST

LCD-

SHLD

-L

O

A

D CE

LL

I

N

P

U

T

S

-

E

X

C

+

E

X

C

+

E

X

C

-

E

X

C

-

C

O

M

S

I

G

/

C

O

M

C.

T.

S

I

G

-

S

H

L

D

S

H

L

D

S

I

G

+

LVDT

INTEGRATOR

RED

BLUE

YELLOW

GREEN

SF500

integrator

Siemens Milltronics LVDT

*

**For Encapsulated LVDT (hazardous)

YEL = WHITE

BLU = ORANGE

GRN = YELLOW

**Junction box included with hazardous-rated unit.

*LVDT

**

Summary of Contents for milltronics ILE-37

Page 1: ...Instruction Manual September 2003 ILE 37 milltronics ...

Page 4: ...ii ...

Page 25: ...Notes ...

Page 26: ...Notes ...

Page 27: ......